Algae growth holds immense promise for producing renewable diesel fuel alternatives. Its biomass serves as a sustainable feedstock for biodiesel, which boasts properties and advantages comparable to fossil fuels. The transesterification process converts algal oil into biodiesel, which can be further refined through hydroprocessing to enhance its quality. Algae-based biofuels offer a potential solution to environmental concerns and energy security, but research and development are ongoing to optimize production and address challenges.

Algae Growth: Harnessing the Promise of Diesel Fuel

- Discuss the significance of algae growth in producing renewable alternatives to traditional diesel fuel.

Algae Growth: Harnessing the Promise of Diesel Fuel

In the realm of renewable energy, the humble algae holds immense promise. With its extraordinary ability to accumulate lipids, this microscopic organism offers a sustainable and abundant feedstock for the production of diesel fuel alternatives. Harnessing the power of algae growth can pave the way for a cleaner and more secure energy future.

Algae’s remarkable lipid content makes it an ideal candidate for biodiesel production. This plant-based fuel boasts properties and advantages that rival traditional fossil fuels. Biodiesel, a clean-burning, biodegradable alternative, is gaining traction as a sustainable solution for transportation.

The key to unlocking the potential of algae lies in the transesterification process. This chemical reaction converts vegetable oils, including algal oil, into biodiesel. By removing impurities and enhancing quality, hydroprocessing further refines algal oil to produce an optimal biodiesel fuel.

As a byproduct of biodiesel manufacturing, glycerin emerges as a valuable commodity. This versatile substance finds applications in a range of industries, from food and pharmaceuticals to personal care products.

Embracing algae-based biofuels holds immense potential for addressing environmental concerns and energy security. Algae cultivation can mitigate carbon emissions, reduce dependence on fossil fuels, and create new opportunities for sustainable economic growth. However, challenges remain in scaling up production and optimizing the conversion processes. By investing in research and innovation, we can unlock the full potential of algae and harness its promise as a renewable diesel fuel alternative.

Unlocking Algal Biomass: A Sustainable Pathway to Biodiesel

In the quest for renewable energy sources, algae emerges as a promising solution, unlocking a vast potential for biodiesel production. Unlike traditional feedstocks such as soybeans, algae offer a sustainable and abundant alternative.

Algae, microscopic organisms found in both fresh and saltwater environments, have a remarkable ability to accumulate lipids, the building blocks of biodiesel. This inherent characteristic makes algae an ideal feedstock for producing this renewable fuel. Their rapid growth rates and high lipid content make algae a viable option for meeting the growing demand for sustainable energy.

Moreover, algae cultivation can be integrated into existing agricultural systems or established in marginal lands unsuitable for traditional farming, minimizing competition for arable land. This dual-use approach not only enhances energy security but also contributes to sustainable land management practices.

The use of algal biomass as a feedstock for biodiesel production offers a plethora of advantages. Algae are a domestically produced resource, reducing reliance on imported fossil fuels and enhancing energy independence. Furthermore, algae cultivation creates new job opportunities, supporting local economies and fostering sustainable development.

Biodiesel: A Viable Alternative to Fossil Fuels

In the quest for sustainable and renewable energy sources, biodiesel has emerged as a promising alternative to traditional fossil fuels. Derived from plant oils or animal fats, biodiesel offers a cleaner and more environmentally friendly option without compromising on performance.

Biodiesel is a type of fuel that is chemically similar to conventional diesel fuel but is produced from renewable sources. It can be used in most diesel engines with minimal or no modifications, providing a seamless transition to a more sustainable fuel option.

One of the key advantages of biodiesel is its biodegradability. Unlike fossil fuels, which are non-biodegradable and can persist in the environment for centuries, biodiesel is naturally broken down by microorganisms, reducing the risk of contamination and environmental damage.

Furthermore, biodiesel has a higher cetane number than conventional diesel fuel, indicating a better ignition quality. This means that biodiesel engines ignite more easily, resulting in smoother operation and reduced emissions. It also has a lower sulfur content, making it more environmentally friendly by emitting fewer harmful sulfur oxides into the atmosphere.

In addition, biodiesel can help to reduce greenhouse gas emissions. When burned, it releases less carbon dioxide than fossil fuels, as the carbon dioxide it produces is part of a closed-loop cycle that involves plant growth and photosynthesis.

Cetane Number: Measuring Diesel Fuel Quality

When it comes to diesel fuel, one key metric that determines its performance is the cetane number. It’s like the octane number for gasoline, but for diesel. Cetane number measures the ease of ignition and combustion quality of a diesel fuel.

A higher cetane number means the fuel ignites more easily and burns more smoothly, leading to:

- Reduced engine noise and vibration

- Improved fuel economy

- Lower emissions

Diesel engines rely on compression ignition, where the high temperature and pressure created by compression ignite the fuel. A high cetane number ensures that the fuel ignites promptly at the optimal point in the compression cycle, rather than detonating prematurely (causing knocking) or igniting too late (resulting in incomplete combustion).

The cetane number of diesel fuel is typically between 40 and 55. Higher cetane numbers are desirable, especially in cold weather conditions where ignition can be more difficult. Additives known as cetane improvers can be used to enhance the cetane number of diesel fuel.

By optimizing the cetane number of diesel fuel, we can improve the performance and efficiency of our diesel engines, leading to reduced emissions and a more environmentally friendly transportation sector.

Transesterification: Unlocking the Magic of Biodiesel Creation

In the realm of renewable energy, algae hold a promising key to unlocking a sustainable alternative to traditional diesel fuel. The transformative power of transesterification, a chemical reaction akin to alchemy, lies at the heart of this conversion process.

Transesterification is a process that transmutes vegetable oils, such as the oil extracted from algae biomass, into biodiesel. This remarkable reaction involves the rearrangement of molecules, replacing the long fatty acid chains of the oil with methyl groups, derived from methanol. The product of this transformation is biodiesel, a clean-burning, renewable fuel that can seamlessly replace fossil diesel.

The process unfolds in the presence of a catalyst, typically a strong base such as sodium hydroxide or potassium hydroxide. These catalysts facilitate the breaking of the bonds between the fatty acids and the glycerol backbone of the vegetable oil.

As the reaction proceeds, glycerin, a valuable byproduct of biodiesel production, is liberated. Glycerin finds myriad applications in the pharmaceutical, cosmetic, and food industries, adding an extra layer of economic value to the transesterification process.

The transesterification reaction is carefully controlled to ensure optimal conversion of the vegetable oil into biodiesel. The ratio of oil to methanol, the reaction temperature, and the catalyst concentration all play a crucial role in maximizing the yield of biodiesel.

Once the transesterification reaction reaches completion, the biodiesel is separated from the glycerin and any remaining impurities. This stage involves a combination of settling, washing, and drying techniques to produce a pure and refined biodiesel fuel.

The resulting biodiesel is a high-quality, renewable alternative to fossil diesel. It possesses excellent cetane number, a measure of ignition quality, and can be blended with conventional diesel fuel without compromising engine performance.

Embracing transesterification as a means of producing biodiesel from algal oil holds immense promise for a more sustainable and energy-secure future. This transformative process not only reduces our reliance on fossil fuels but also opens up new avenues for innovation and economic growth.

Hydroprocessing: Refining Algal Oil for Optimal Biodiesel

In the pursuit of sustainable energy alternatives, algae-based biofuels hold immense promise. Hydroprocessing, a crucial step in the production of biodiesel from algal oil, plays a pivotal role in refining this renewable fuel to meet the exacting standards of diesel engines.

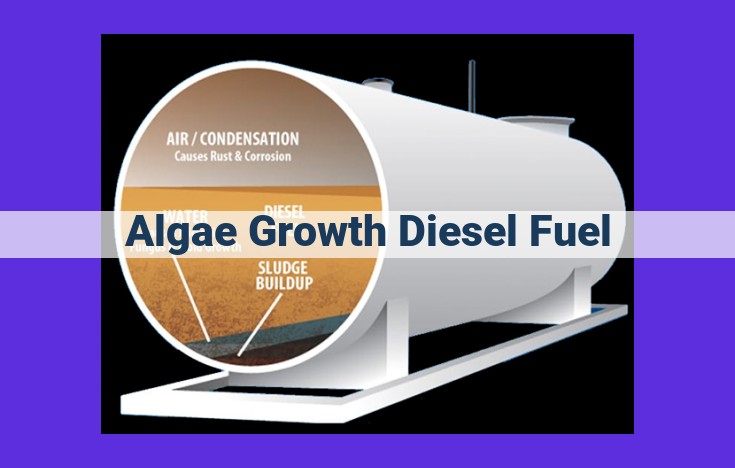

Algal oil, teeming with valuable lipids, serves as the foundation for biodiesel production. However, impurities and contaminants lurking within this oil can compromise the quality and performance of the resulting biodiesel. Enter hydroprocessing, a masterful process that purifies algal oil, removing unwanted elements and leaving behind a pristine, high-performance biofuel.

Hydroprocessing employs catalytic reactions under elevated temperatures and pressures to transform algal oil. These catalytic wizards work tirelessly, cleaving carbon-carbon double bonds, reducing oxygen content, and saturating the oil with hydrogen. As a result, impurities such as free fatty acids, gums, and other contaminants are eliminated, leaving behind a refined, stable biodiesel.

The benefits of hydroprocessed algal biodiesel cannot be overstated. It boasts a high cetane number, a measure of ignition quality, ensuring optimal engine performance. Its low sulfur content contributes to cleaner emissions, reducing environmental pollution. Furthermore, hydroprocessed biodiesel exhibits excellent stability, resisting oxidation and degradation over time, ensuring its longevity and storage capabilities.

Thus, hydroprocessing stands as a guardian of biodiesel quality, transforming algal oil into a renewable fuel that rivals and even surpasses conventional diesel in performance. As we navigate the path toward a sustainable energy future, the role of hydroprocessing in unlocking the potential of algae-based biofuels cannot be underestimated.

Glycerin: The Versatile Byproduct of Biodiesel Production

In the realm of biodiesel production, glycerin often takes a backseat to the primary fuel. However, this unassuming byproduct holds a wealth of potential, boasting a range of versatile applications that extend far beyond its role in fuel manufacturing.

During the transesterification process that transforms vegetable oils into biodiesel, glycerin is produced as a natural byproduct. This viscous, colorless liquid possesses a sweet taste and a wide array of industrial and consumer uses.

One of the most notable applications of glycerin is in the pharmaceutical industry. It serves as a humectant in cough syrups and other medications, helping to retain moisture and prevent irritation. Additionally, glycerin is used as a solvent in the production of antibiotics and other drugs.

Beyond pharmaceuticals, glycerin finds its way into countless personal care products. Its moisturizing properties make it a popular ingredient in soaps, lotions, and creams. Glycerin also acts as a lubricant in toothpaste and shaving cream, ensuring a smooth and comfortable experience.

In the food industry, glycerin is employed as a sweetener in low-calorie foods and beverages. It also functions as a glazing agent in candies and baked goods, giving them a shiny and appealing appearance.

Furthermore, glycerin has industrial applications in the production of plastics, paints, and textiles. It serves as a lubricant in machinery and as a solvent in various industrial processes.

In conclusion, glycerin is a versatile and valuable byproduct of biodiesel production. Its wide range of applications spans industries and encompasses products that touch our daily lives in numerous ways. From pharmaceuticals to personal care products, food to industrial materials, glycerin quietly plays a significant role in our modern world. Embracing algae-based biofuels not only provides a renewable alternative to fossil fuels but also contributes to the sustainable and efficient utilization of resources, including the production of this versatile and essential byproduct.