AWG8 wire junction boxes are electrical enclosures that house connections between 8 AWG (American Wire Gauge) wires. AWG8 wire has a diameter of 0.162 inches, a cross-sectional area of 10.5 square millimeters, and is typically made of copper. Junction boxes are used to protect wire connections from damage and provide a convenient point for making changes or adding new circuits. AWG8 wire is commonly used in these boxes due to its capacity to carry high currents (up to 40 amps) and voltage (up to 600 volts). It is essential to consider insulation type, flexibility, and construction (stranded vs. solid) when selecting AWG8 wire for junction boxes. Adhering to local building codes and understanding wire size terminology ensures safe and efficient electrical installations.

Defining AWG8 Wire: A Guide to Wire Size and Specifications

In the realm of electrical wiring, understanding wire size is paramount for safe and efficient installations. AWG (American Wire Gauge) is the industry standard system used to measure wire size, providing a comprehensive set of specifications for various applications.

AWG8 wire is a medium-sized wire commonly employed in residential and commercial electrical systems. Its diameter measures approximately 0.128 inches, with a cross-sectional area of 8800 circular mils. Typically made of copper, AWG8 wire offers excellent conductivity and is often stranded, consisting of multiple fine strands to enhance flexibility.

Understanding Wire Size Terminology

When selecting wire, it’s crucial to consider its voltage rating, which indicates the maximum voltage it can withstand without insulation breakdown. AWG8 wire typically has a voltage rating of 600 volts for both stranded and solid constructions. Its amperage rating, another critical specification, determines the maximum current it can carry continuously without overheating. For AWG8 wire, the amperage rating is 40 amps for stranded wire and 50 amps for solid wire.

Understanding Wire Size Terminology

The Significance of AWG8 Wire Specifications

AWG8 wire is not just a random assortment of letters and numbers; it represents a precise set of specifications that dictate its electrical capabilities. These specifications include the number of conductors, voltage rating, and amperage rating. Each of these factors plays a crucial role in determining the wire’s suitability for specific applications.

Number of Conductors

AWG8 wire can have either a single conductor or multiple conductors twisted together. A single-conductor wire is typically used when the wire will not be subject to frequent bending or flexing. Multiple-conductor wire is more flexible and can withstand repeated bending without breaking.

Voltage Rating

The voltage rating of AWG8 wire refers to the maximum voltage it can safely withstand without breaking down. This voltage rating is determined by the insulation material used on the wire. Common voltage ratings for AWG8 wire include 300 volts, 600 volts, and 1000 volts.

Amperage Rating

The amperage rating of AWG8 wire refers to the maximum current it can safely carry without overheating. This amperage rating is determined by the cross-sectional area of the wire. The larger the cross-sectional area, the higher the amperage rating.

Impact on Wire Capabilities and Applications

These specifications work in conjunction, defining the wire’s overall capabilities and suitable applications. For example, a single-conductor AWG8 wire with a 300-volt rating and a 10-ampere rating would be suitable for low-voltage lighting applications. However, if the same wire were used in a high-voltage circuit, it could overheat and become a fire hazard.

Understanding these specifications is essential for selecting the correct AWG8 wire for your project, ensuring the safety and efficiency of your electrical installations.

AWG8 Wire in Junction Boxes: Connecting Electrical Components Safely

Introduction:

In the intricate world of electrical installations, junction boxes serve as the central hubs, connecting electrical components and allowing for the smooth flow of energy. Selecting the right wire for these crucial junctions is paramount for safety and efficiency. AWG8 wire, with its specific characteristics and capabilities, plays a vital role in ensuring the seamless functionality of these electrical pathways.

Purpose of Junction Boxes:

Junction boxes are the unsung heroes of electrical systems, providing a safe and organized enclosure for connecting wires and protecting them from external hazards. They act as central meeting points, allowing multiple wires to converge and be distributed to various electrical components, such as switches, outlets, and fixtures.

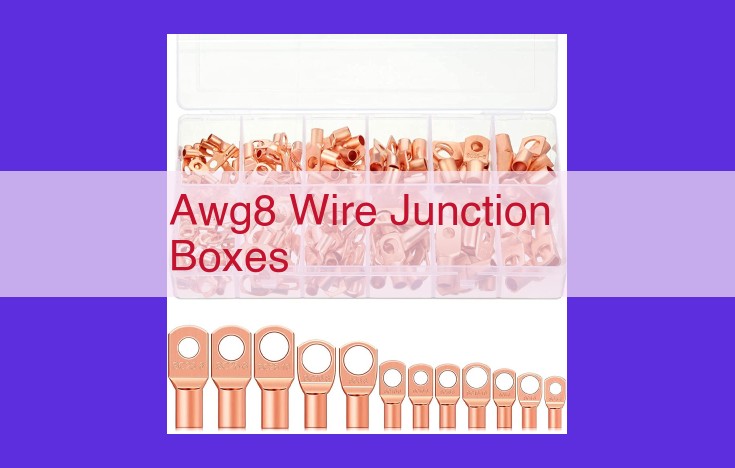

AWG8 Wire: A Trusted Choice for Junction Boxes:

Among the various wire sizes available, AWG8 wire stands out as an ideal choice for junction boxes due to its optimal balance of size and current-carrying capacity. Its larger diameter and increased cross-sectional area allow it to handle higher currents than smaller gauges, ensuring that the electrical connections within the junction box are secure and efficient.

Considerations for Selecting AWG8 Wire:

When selecting AWG8 wire for junction boxes, several factors must be carefully considered. The number of conductors, voltage rating, and amperage rating of the specific electrical installation should be taken into account. These specifications determine the wire’s ability to safely carry the electrical load without overheating or causing a fire hazard.

Conclusion:

Understanding the importance of AWG8 wire in junction boxes is crucial for safe and effective electrical installations. By considering the purpose of junction boxes, the characteristics of AWG8 wire, and the relevant selection factors, homeowners and electricians can ensure that their electrical systems operate smoothly and reliably for years to come.

Additional Factors to Consider When Using AWG8 Wire in Junction Boxes

In addition to the essential specifications discussed earlier, several other factors play a crucial role in selecting the most suitable AWG8 wire for your junction box applications. Let’s delve into these essential considerations:

Insulation Type

The insulation surrounding the wire is paramount for electrical safety and performance. Different types of insulation materials, such as PVC, XLPE, or EPR, offer varying degrees of protection against moisture, heat, and mechanical damage. Choose the insulation type appropriate for the environment and application to ensure long-term reliability.

Flexibility

Flexibility is a key factor to consider, especially in tight spaces and complex wiring configurations. Solid wire provides maximum current-carrying capacity but has limited flexibility, while stranded wire is more flexible and easier to maneuver, making it ideal for intricate installations.

Stranded vs. Solid Wire Construction

The choice between stranded and solid wire depends on the specific application. Solid wire offers higher conductivity and is suitable for short, straight runs. Stranded wire, composed of multiple thin strands, provides greater flexibility and is preferred for longer runs, connections subject to vibration, or where bending is required.

Adhering to Local Building Codes

It’s imperative to comply with local building codes when using AWG8 wire in junction boxes. These codes ensure the safety and integrity of electrical installations by specifying the minimum wire size, insulation requirements, and proper installation practices. Failure to adhere to these codes could compromise the safety and functionality of your electrical system.