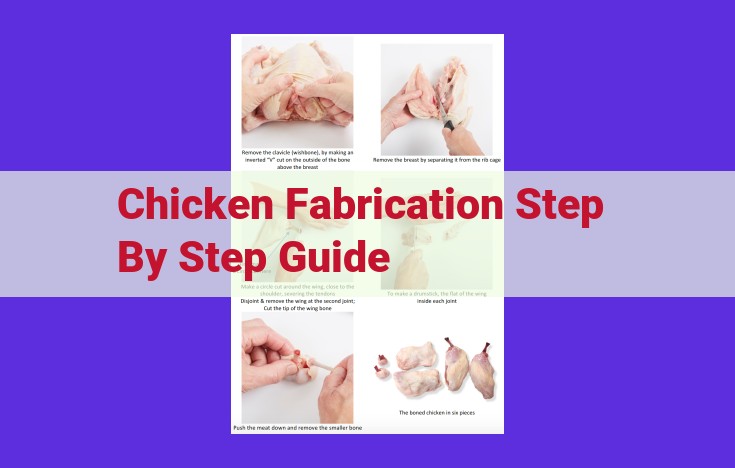

Chicken Fabrication Step-by-Step Guide

Follow this comprehensive guide to master the art of chicken fabrication. Chill the slaughtered chicken promptly, then scald and defeather it effectively to enhance product quality. Proceed with evisceration, removing the digestive system and organs. Ensure sanitation by inspecting and thoroughly washing the chicken. Re-chill to minimize bacterial growth. Consider further processing options to add value and enhance flavor. By meticulously following these steps, you’ll achieve optimal results in chicken fabrication for efficient and safe meal preparation.

Discuss the significance of chicken fabrication and its benefits for efficient meal preparation.

Chicken Fabrication: A Culinary Delicacy for Efficient Meal Preparation

In the culinary world, efficiency is key. Enter: chicken fabrication, the art of preparing chickens for cooking. It’s not just about slicing and dicing; it’s a meticulous process that enhances the quality and safety of your meals.

The Benefits of Chicken Fabrication

- Time Savings: Pre-fabricated chickens save hours in the kitchen, allowing you to focus on other culinary delights.

- Reduced Waste: By removing unwanted parts, you minimize waste and maximize the utilization of your chicken.

- Enhanced Flavor: Properly fabricated chickens allow for even cooking, resulting in succulent dishes with delectable flavors.

- Safer Meals: Correct fabrication techniques minimize the risk of cross-contamination, ensuring that your meals are safe for consumption.

By understanding the steps involved in chicken fabrication, you’ll become a culinary wizard in no time. Let’s dive into the essential stages and discover the secrets of perfect chicken preparation.

Best Outline for Blog Post on Chicken Fabrication

1. Chilling: Maintaining the Cold Chain

- Chilling chickens immediately after slaughter is crucial to prevent spoilage and ensure food safety.

- Efficient chilling methods, like immersion chilling, rapidly lower the chicken’s temperature.

2. Scalding and Defeathering: Enhancing Product Quality

- Scalding simplifies feather removal and minimizes carcass damage compared to plucking.

- Controlled scalding and defeathering techniques maximize efficiency and product yield.

3. Evisceration: Removing Internal Organs

- Evisceration involves the careful removal of internal organs like the digestive system and organs.

- Proper gutting techniques ensure a clean and sanitary carcass.

4. Inspection and Washing: Ensuring Sanitation and Hygiene

- Thorough inspection detects any abnormalities or contamination after evisceration.

- Washing removes blood and residues, guaranteeing a hygienic product.

5. Chilling and Packaging: Preserving Quality for Storage

- Chilling after evisceration further inhibits bacterial growth.

- Vacuum sealing and other packaging methods maintain quality and extend shelf life.

6. Further Processing (Optional): Value Addition and Enhanced Flavor

- Marinating, smoking, or curing enhances flavor and adds value to chicken products.

- Experimenting with different processing methods broadens culinary options.

- Chicken fabrication involves meticulous attention to detail and hygiene.

- By following these steps, home cooks and professionals can produce safe and high-quality chicken preparations.

Chilling Chickens: The Key to Safe and Flavorful Fabrication

When it comes to preparing mouthwatering chicken dishes, the process starts well before the marinade or seasoning. Chilling chickens is a crucial step that not only ensures the safety of the meat but also enhances its flavor and texture.

After slaughter, chilling chickens as soon as possible is paramount to prevent the growth of harmful bacteria. Poultry is particularly susceptible to rapid spoilage, and chilling slows down microbial activity. When chickens are chilled promptly, the cold temperatures inhibit bacterial proliferation, preventing foodborne illnesses.

Moreover, the chilling process has a profound impact on the quality of the meat. Chilling chickens helps to contract the muscles, resulting in a firmer and juicier end product. It also prevents protein denaturation, which can cause the chicken to become tough and tasteless.

There are several effective methods for chilling chickens. Immersion chilling is a commonly used technique where the chickens are submerged in chilled water, typically between 32-40°F (0-4°C). This method rapidly cools the chickens, ensuring a consistent and effective chill.

Proper chilling is not only a safety measure but also enhances the flavor and tenderness of the chicken. By chilling chickens as soon as possible, you are ensuring a safe, delicious, and succulent dining experience.

Chilling: Maintaining the Cold Chain for Safe and Fresh Chicken

When it comes to chicken fabrication, chilling is an essential step that ensures your poultry remains fresh and safe to consume. It slows down microbial growth and prevents spoilage, extending the shelf life of your chicken.

Immersion chilling is one of the most effective chilling methods used in chicken fabrication. It involves submerging the freshly slaughtered chickens in cold water or a cooling solution. This rapid immersion helps to bring down the carcass temperature quickly and evenly, minimizing the risk of bacterial proliferation.

The temperature of the chilling water or solution is crucial. It should be kept below 40°F (4°C) to effectively inhibit bacterial growth. The chilling process typically takes several hours, depending on the size and weight of the chickens.

Immersion chilling offers several advantages over other methods. It provides uniform cooling, ensuring that all parts of the chicken are chilled thoroughly. This helps to prevent cold spots, where bacteria can thrive. Additionally, immersion chilling reduces carcass damage, as there is no physical manipulation of the birds during the process.

By following proper immersion chilling techniques, you can maintain the cold chain and deliver high-quality, safe chicken to your customers or for your own consumption. Remember, meticulous chilling is a vital step in chicken fabrication, safeguarding the freshness and safety of this versatile and delicious protein.

Best Practices for Chicken Fabrication: Scalding Over Plucking

When it comes to prepping succulent chicken dishes, meticulous fabrication is paramount. One crucial step in this process is the removal of feathers. While plucking has been a traditional method, scalding has emerged as a superior choice, offering improved feather removal and reduced carcass damage.

Enhanced Feather Removal with Scalding

Scalding involves submerging chickens in hot water, which acts as a natural lubricant. As the feathers come into contact with the heated water, the keratin proteins that bind the feathers to the skin become weakened. This allows for easy and efficient feather removal, leaving the carcass intact.

Reduced Carcass Damage with Scalding

Unlike plucking, which can cause tearing and bruising, scalding gently loosens the feathers without damaging the delicate chicken skin. This is because the hot water penetrates the feather follicles, where the feathers are attached, softening the surrounding tissues. As a result, the feathers are easily removed with minimal force, preserving the integrity of the carcass.

Time-Saving and Cost-Effective

Scalding is also more time-saving compared to plucking. The hot water quickly penetrates the feathers, allowing for rapid removal. This is especially advantageous for large-scale poultry processing operations, where efficiency is key.

Improved Hygiene and Sanitation

Scalding plays a crucial role in maintaining hygiene and sanitation. The high temperature of the water kills bacteria and other microorganisms that may be present on the chicken’s surface. This ensures a cleaner and safer product for consumers.

In summary, scalding offers significant advantages over plucking in chicken fabrication. It not only improves feather removal but also reduces carcass damage, saves time, and enhances hygiene. By embracing scalding as the preferred method, you can ensure the highest quality chicken products for your culinary creations.

Optimize Chicken Fabrication: Mastering Scalding and Defeathering for Efficiency

The Art of Scalding

As you embark on your chicken fabrication journey, mastering the art of scalding holds the key to efficient feather removal and minimized carcass damage. The process involves immersing the freshly slaughtered chicken in hot water, typically between 58°C and 65°C (136°F and 149°F). This brief plunge helps loosen the feathers, making them easier to remove.

Effective Scalding Techniques

There are two primary scalding methods to choose from:

-

Immersion scalding: Submerge the entire chicken in the hot water for 30 to 60 seconds. This is the most common method and provides consistent feather removal.

-

Spray scalding: Use a high-pressure spray of hot water to loosen the feathers. This method can be more efficient for larger operations, as it reduces the time required for scalding.

Defeathering with Precision

Once the chicken has been scalded, it’s time for defeathering. This involves removing the loosened feathers using a combination of mechanical and manual techniques.

Mechanical defeathering utilizes rotating rubber fingers or brushes that gently pull off the feathers. This is an efficient method for large-scale operations.

For manual defeathering, hold the chicken firmly and use your fingers or a tweezer to remove the remaining feathers. This method is best suited for smaller-scale fabrication or for delicate areas where mechanical defeathering may damage the carcass.

Tips for Minimizing Product Loss

- Control the Water Temperature: Scald the chickens at the optimum temperature range to avoid overcooking or undercooking, which can lead to feather loss and skin damage.

- Avoid Overcrowding: Prevent the chickens from bumping into each other during scalding, as this can cause skin tears and reduce feather removal efficiency.

- Thorough Defeathering: Carefully inspect the chicken after mechanical defeathering and remove any remaining feathers by hand to ensure a clean and presentable product.

Evisceration: Removing Internal Organs for a Healthier, Tastier Meal

Evisceration is an indispensable step in chicken fabrication, ensuring the safe and sanitary consumption of this beloved poultry. It involves the meticulous removal of internal organs, including the digestive system, to maintain the bird’s integrity and enhance flavor.

Upon arriving at the processing facility, chickens are usually stunned and bled to facilitate evisceration. The process begins by creating a small incision in the abdominal cavity, exposing the intestines and other organs. Using specialized tools, skilled technicians carefully extract the digestive tract, including the stomach, intestines, and cloaca. The liver, which plays a crucial role in metabolism, is also removed along with the heart and sometimes the lungs.

Evisceration is essential for several reasons. First and foremost, it removes potential sources of bacteria and pathogens that can contaminate the meat and pose health risks to consumers. By eliminating the digestive organs, the risk of cross-contamination is significantly reduced, ensuring the safety and wholesomeness of the chicken.

Moreover, evisceration enhances the taste and texture of the meat. Removing the digestive system eliminates the bitter flavors that can accumulate in these organs, resulting in a more palatable and enjoyable eating experience. Additionally, it improves the appearance of the chicken, making it more appealing to the eye.

Proper evisceration requires meticulous attention to detail and strict adherence to food safety standards. Technicians must ensure that the digestive tract is completely removed, avoiding any punctures or tears that could compromise the integrity of the meat. Furthermore, the cavity must be thoroughly cleaned to remove any residual blood or contents, ensuring the highest levels of hygiene.

By following these guidelines, poultry processors can ensure that their chicken products meet the highest standards of safety, quality, and taste, providing consumers with a healthy and satisfying culinary experience.

The Art of Chicken Fabrication: A Step-by-Step Guide to Evisceration

Embarking on the Culinary Journey

As we delve into the realm of chicken fabrication, embarking on the meticulous task of evisceration is paramount. This crucial step involves removing the internal organs of the chicken, ensuring not only its cleanliness but also its culinary potential. Let us guide you through the proper gutting process, a key component in the preparation of a safe and delectable dish.

Unraveling the Chicken’s Core: The Gutting Process

With a steady hand and utmost care, we begin the gutting process. First, locate the vent, a small opening at the rear of the chicken. Using a sharp knife, carefully cut around the vent, making a circular incision. Gently insert your fingers into the opening and loosen the intestines, taking caution not to rupture them.

With deft movements, pull out the intestines, allowing them to unravel from the cavity. Inspect the intestines thoroughly for any abnormalities. The next step is to remove the gizzard, a small organ located near the stomach. Carefully cut away the connecting tissue and remove it.

Navigating the Gastrointestinal Tract: Stomach and Heart Removal

The next organ to be removed is the stomach, which is located to the right of the gizzard. Using your knife, cut around the stomach and gently pull it free from the surrounding tissue. Once the stomach has been removed, locate the heart, which is situated at the top of the cavity. Carefully cut away the connecting blood vessels and remove the heart.

By following these steps meticulously, you have successfully eviscerated the chicken. This process not only ensures the cleanliness and safety of the bird but also paves the way for tantalizing culinary creations.

Remember, chicken fabrication is an art that requires precision and attention to detail. By embracing these techniques, you can unlock the full potential of this versatile ingredient, transforming it into a symphony of flavors in your culinary endeavors.

Ensuring Sanitation and Hygiene: The Importance of Chicken Inspection

Maintaining the highest standards of sanitation and hygiene is paramount throughout the chicken fabrication process. After evisceration, a thorough inspection is crucial to ensure that the chicken is free from any abnormalities or contaminants that could compromise its safety or quality. This meticulous examination helps prevent the spread of foodborne illnesses, protects consumers, and upholds the integrity of your products.

Trained Eyes for Quality Control

Skilled inspectors carefully examine each chicken after evisceration, paying close attention to its internal and external surfaces. They check for any signs of bruising, tearing, or abnormalities that may indicate improper handling or disease. Additionally, the organs are closely inspected for any signs of infection or contamination.

Detecting Contaminants

Thorough inspection also helps detect any foreign objects or contaminants that may have entered the chicken during processing. These contaminants can range from feathers and bone fragments to pieces of equipment or packaging materials. Removing these contaminants ensures that the chicken is safe for consumption and meets the highest quality standards.

Protecting Your Business

Conducting thorough inspections is not only a matter of food safety but also of protecting your business. By detecting and removing any potential hazards, you can prevent recalls, product withdrawals, and damage to your brand’s reputation. It also demonstrates your commitment to providing safe and wholesome chicken products to your customers.

Hygiene and Cleanliness

The inspection process is conducted in a clean and hygienic environment to prevent cross-contamination. Inspectors wear protective clothing and follow strict sanitation protocols to ensure that the chicken remains free from any additional contaminants. This attention to detail ensures that the chicken is handled with the utmost care and meets the highest standards of safety and hygiene.

Ensuring Sanitation and Hygiene: Washing Chickens for a Sanitary Product

After evisceration, washing the chickens is a critical step in ensuring a sanitary product. This process removes blood, residues, and any remaining contaminants to prevent spoilage and guarantee the safety of the final product.

Step-by-Step Process for Washing Chickens

-

Prepare a Washing Station: Designate a specific area with ample space for washing. Equip this station with a sink or large container filled with clean, cold water.

-

Rinse Thoroughly: Submerge the chickens in the water and gently rinse them. Use a hose or a jug to pour water over the carcasses, ensuring all surfaces are covered.

-

Remove Contaminants: Carefully inspect the chickens as you rinse. Remove any remaining feathers, blood clots, or other contaminants by hand or with a clean cloth.

-

Brush and Scrub: Use a soft-bristled brush to remove any stubborn residues. Gently scrub the chickens, paying particular attention to the crevices and joints where contaminants may linger.

-

Rinse Again: Submerge the chickens in the water once more and rinse them thoroughly to remove any loosened contaminants. Continue rinsing until the water runs clear.

-

Drain and Dry: Remove the chickens from the water and drain them on a clean surface. Use paper towels or a clean cloth to pat dry the exterior of the carcasses.

By following these steps, you ensure that your chickens are thoroughly cleaned and sanitized, minimizing the risk of contamination and extending their shelf life.

Chilling: Preserving Quality and Safety

After the crucial step of evisceration, where the internal organs are removed, chilling the chicken again is paramount to maintain its quality and ensure its safety for consumption. This second chilling process is an essential part of chicken fabrication and should not be overlooked.

Chilling the chicken after evisceration prevents the growth of spoilage-causing microorganisms by slowing down their metabolic rate. This is particularly important because evisceration exposes the chicken to open air, making it more susceptible to microbial contamination. Chilled temperatures inhibit the growth of these microorganisms, extending the shelf life of the chicken and preventing foodborne illnesses.

Benefits of Chilling After Evisceration

The primary benefit of chilling after evisceration is to ****further reduce microbial growth** on the chicken carcass. This is achieved by reducing the temperature of the chicken to a point where microbial growth is significantly slowed down or halted. This inhibits the growth of potential pathogens, such as Salmonella and Campylobacter, which can cause foodborne illnesses if consumed.

Chilling also helps to ****maintain the quality** of the chicken by preventing enzymatic reactions that can lead to deterioration. These reactions can cause the chicken to lose its natural flavors and textures, resulting in a lower-quality product. Chilling slows down these reactions, preserving the chicken’s freshness and overall eating experience.

Packaging for Preserving Poultry Perfection

Vacuum Sealing: The Seal of Freshness

- Vacuum sealing is the knight in shining armor for maintaining the pristine quality of your poultry.

- By removing the air from the packaging, minimizing oxidation, it becomes an impenetrable fortress against spoilage, ensuring your chicken remains flavorful and succulent.

Modified Atmosphere Packaging: Breathing New Life into Poultry

- Modified atmosphere packaging is the breath of fresh air for your chicken.

- This technique alters the gas composition within the package, creating an optimal environment that slows down spoilage and extends shelf life.

Skin Packaging: A Second Skin for Your Poultry

- Skin packaging is the perfect fit for poultry that deserves to be shown off.

- The film clings tightly to the contour of the chicken, preserving both its shape and appealing presentation.

Cryovac Packaging: Shrink-Wrapped to Perfection

- Cryovac packaging is the shrink-to-fit solution for poultry that needs a snug hug.

- This packaging conforms to the shape of the chicken, protecting it from external damage while maximizing space during storage and transportation.

Choosing the Right Packaging for Your Poultry

- The key to optimal preservation lies in tailoring your packaging to the specific needs of your poultry.

- Consider factors such as product type, storage conditions, and desired shelf life to make an informed decision.

By employing these packaging techniques, you can extend the lifespan of your poultry, preserve its flavor, and maintain its pristine appearance. So, go forth, embrace the art of poultry packaging, and savor the delicious rewards of meticulous fabrication.

Explain the reasons for further processing chickens, such as marinating, smoking, or curing.

Further Processing: Elevating Flavor and Appeal

Beyond the essential steps of fabrication, further processing takes chicken to another level, transforming it into culinary delights. From marinating to smoking and curing, these techniques enhance flavor, tenderize textures, and create mouthwatering options.

Marinating:

Immersing chicken in a flavorful liquid, marinades infuse meats with aroma and moisture. Marinades typically consist of acids (e.g., vinegar, lemon juice), herbs, spices, and oils that penetrate the chicken, resulting in juicy, succulent dishes. Marinating time varies depending on the marinade strength and the desired depth of flavor.

Smoking:

The smoky allure of grilled chicken is achieved through smoking, a process that imparts a rich, earthy flavor. Chickens are placed in a smoker, exposing them to smoke from burning woods like hickory, oak, or mesquite. Smoking tenderizes the meat while adding a distinctive smoky aroma and taste.

Curing:

Curing is a traditional method of preserving meats by adding salt, sugar, and other spices. This process inhibits bacterial growth, extends shelf life, and develops a unique savory flavor. Cured chicken can be enjoyed in various forms, such as bacon, ham, or jerky.

By embracing further processing techniques, you unlock a world of culinary possibilities. Marinated chicken transforms into tender kebabs or grilled masterpieces. Smoked chicken becomes the star of backyard barbecues, adding an irresistible flavor to dishes. Cured chicken offers a flavorful and convenient option for sandwiches, snacks, and charcuterie boards.

Further Processing: A Culinary Canvas for Flavor and Texture

Beyond the basic steps of fabrication, further processing techniques provide a world of culinary possibilities. Imagine adding a touch of smoke, a hint of spice, or a burst of herbs to your chicken dishes. Here are a few examples to whet your appetite:

Marinating:

- Soaking chickens in flavorful liquids, such as buttermilk, olive oil, or soy sauce, infuses them with *moisture and deliciousness*.

- Marinating times can vary depending on the desired intensity of flavor, but even a few hours can make a significant difference.

Smoking:

- Exposing chickens to smoke adds a *rich, aromatic flavor and tenderizes the meat*.

- From classic barbecue to delicate smoked chicken breast, there’s a smoke profile for every palate.

Curing:

- Preserving chickens with salt or other curing agents enhances their *flavor and shelf life*.

- Cured chicken can be cooked or sliced thin for salads, sandwiches, or as a flavorful snack.

Other Methods:

- Roasting: Cooking chicken in an oven or on a rotisserie yields *crispy skin and juicy meat*.

- Frying: Submerging chicken in hot oil creates a *golden-brown exterior and tender interior*.

- Braising: Simmering chicken in a flavorful liquid results in *fall-off-the-bone succulence*.

By experimenting with these further processing techniques, you can transform ordinary chicken into culinary masterpieces. Whether you prefer the delicate flavors of marinating or the bold smokiness of grilling, there’s a processing method that will elevate your cooking experience. Embrace the flavors, textures, and culinary possibilities that further processing offers.

Chicken Fabrication: A Detailed Guide to Expert Meal Preparation

Meticulous chicken fabrication is an art that transforms ordinary poultry into culinary masterpieces. By understanding and implementing the critical steps involved, you can enjoy the benefits of efficient meal preparation, reduced food waste, and enhanced flavor.

Essential Steps for Impeccable Chicken Fabrication

1. Maintaining the Cold Chain: Chilling

Preserving chicken quality begins with chilling immediately after slaughter. This prevents spoilage by slowing microbial growth. Effective chilling methods like immersion chilling ensure that the chicken remains at a safe temperature throughout the fabrication process.

2. Enhancing Product Quality: Scalding and Defeathering

Scalding chicken in hot water loosens feathers for easy removal. This technique minimizes carcass damage compared to plucking. Proper scalding and defeathering techniques maximize product quality and reduce waste.

3. Removing Internal Organs: Evisceration

Evisceration involves carefully removing the chicken’s digestive system and other internal organs. Gutting should be done with precision to minimize contamination and ensure the chicken’s hygiene.

4. Ensuring Sanitation: Inspection and Washing

After evisceration, the chicken must be thoroughly inspected for any abnormalities or contaminants. Washing removes blood and other residue, ensuring a clean and sanitary product.

5. Preserving Quality: Chilling and Packaging

Chilling the chicken again after evisceration further slows microbial growth. Vacuum sealing and other packaging methods prolong shelf life and maintain the chicken’s freshness.

Chicken fabrication is not merely a chore but a skill that elevates the dining experience. By following these critical steps and paying meticulous attention to detail and hygiene, you can create delicious and nutritious chicken dishes with confidence and efficiency. Embrace the art of chicken fabrication and unlock a world of culinary possibilities.

Encourage readers to apply the provided guidelines in their own chicken fabrication practices for safe and efficient meal preparation.

Best Outline for Blog Post on Chicken Fabrication

The art of chicken fabrication unfolds like a culinary origami with meticulous steps to transform a whole bird into a symphony of succulent flavors. It’s an essential skill that unlocks the symphony of flavors hidden within the humble chicken.

Chilling: The Cold Chain’s Guardian

Immediately after slaughter, chilling the chicken is paramount to preserve its freshness and safety. Immersion chilling swiftly reduces the bird’s temperature, slowing down bacterial growth and maintaining its wholesome quality.

Scalding and Defeathering: Unveiling the Bird’s Beauty

Scalding, a process that immerses the chicken in hot water, loosens the feathers, making defeathering a breeze. This gentle approach minimizes carcass damage, preserving the chicken’s integrity.

Evisceration: Removing Nature’s Inner Workings

Evisceration meticulously removes the digestive system and organs, preparing the chicken for the final stages of fabrication. With precision, the gutting process ensures the removal of potential contaminants, leaving only the essential flesh.

Inspection and Washing: Hygiene’s Guardians

After evisceration, a thorough inspection is crucial to detect any abnormalities. Washing removes lingering blood and residues, ensuring a sanitary product ready for further processing.

Chilling and Packaging: Preserving Perfection

Post-evisceration chilling further retards microbial growth, ensuring the chicken’s freshness. Vacuum sealing or other packaging methods extend its shelf life, preserving its delectable flavors for later enjoyment.

Further Processing: Enhancing Culinary Delights (Optional)

Additional processing techniques elevate the chicken’s flavor profile. Marinating infuses it with herbs and spices, smoking imparts a rich, smoky aroma, and curing transforms it into a savory delicacy. The possibilities are endless, each method unlocking unique flavors and textures.

Chicken fabrication is a culinary symphony that transforms a raw bird into a culinary masterpiece. By carefully following these steps, you can master the art of meticulous fabrication, ensuring safe and efficient meal preparation. Apply the guidelines outlined in this blog post to unlock the true culinary potential of chicken, enriching your meals with flavors that will delight your palate.