Understanding the dimensions of rubber tracks is crucial for vehicle performance, as they impact speed, traction, stability, and durability. Track dimensions include length, width, pitch, gauge, and height, which influence ground contact area, ride quality, obstacle-crossing capability, and proper fit. Additionally, the number of track links, link type, and track tension affect suspension performance, traction, and wear, while factors like length and width contribute to track wear over time.

Track Dimensions

- Explain the importance of track dimensions for vehicle performance.

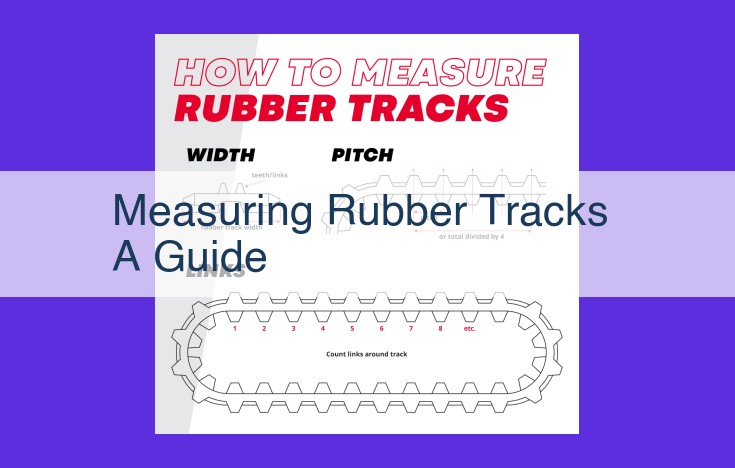

- Discuss the various measurements involved: length, width, pitch, gauge, and height.

Track Dimensions: The Foundation of Vehicle Performance

In the realm of tracked vehicles, their dimensions play a crucial role in determining overall performance, efficiency, and safety. These dimensions, including length, width, pitch, gauge, and height, form the foundation upon which the vehicle’s capabilities rest.

Length influences both speed and ground contact area. Longer tracks provide greater speed and stability, while shorter tracks enhance maneuverability.

Width is paramount for traction and stability. Wider tracks offer increased traction, enabling vehicles to traverse various terrain conditions effortlessly.

Pitch directly impacts ride quality and durability. A finer pitch provides a smoother ride, while a coarser pitch enhances durability by reducing wear and tear.

Gauge ensures proper fit and steering control. Maintaining the correct gauge is essential for optimal steering and handling characteristics.

Height determines ground clearance and obstacle-crossing capability. Taller tracks provide higher ground clearance, allowing vehicles to navigate uneven terrain and overcome obstacles with ease.

Track Length: Balancing Speed and Ground Contact

The length of a track has a significant impact on the performance of tracked vehicles. It influences both speed and ground contact area, affecting stability, traction, and overall vehicle capabilities.

Longer tracks provide a larger ground contact area, resulting in increased stability by distributing the vehicle’s weight over a broader surface. This is particularly advantageous in soft or uneven terrain, where the vehicle is less likely to sink or lose traction. However, longer tracks can also lead to increased rolling resistance, reducing the vehicle’s speed.

Conversely, shorter tracks reduce ground contact area but improve speed by decreasing rolling resistance. This is more suitable for vehicles designed for high-speed operation on relatively firm surfaces, such as racing tracks or paved roads.

Understanding the relationship between track length and ground contact area is crucial for optimizing vehicle performance. The ideal track length depends on the intended use of the vehicle, considering trade-offs between speed, stability, and terrain conditions.

In addition, track length is related to other track dimensions such as width, pitch, gauge, and link design. These factors collectively determine the overall performance and handling characteristics of the tracked vehicle.

Track Width: A Vital Aspect of Traction and Stability

In the realm of tracked vehicles, where navigating diverse terrains is paramount, track width emerges as a crucial factor influencing both traction and stability. Imagine yourself traversing rugged landscapes or navigating through slippery conditions – the width of your vehicle’s tracks will significantly impact its ability to maintain grip and resist tipping over.

A wider track, measured from the outer edge of one track to the outer edge of the other, provides a larger contact area with the ground. This increased contact area enhances traction, allowing the vehicle to generate more forward and braking force. It’s like having a pair of oversized snowshoes, distributing your weight more evenly and preventing you from sinking into soft snow.

Moreover, track width plays a pivotal role in stability. A wider track creates a lower center of gravity, making the vehicle less likely to tip over when traversing side slopes or navigating uneven surfaces. Picture a tall and narrow ladder versus a squat and wide ladder – the latter is undoubtedly more difficult to topple over.

The relationship between track width and stability is particularly evident in tracked vehicles used for military or off-road purposes. These vehicles often operate in challenging terrain, where stability and traction are essential for maneuverability and safety.

However, it’s important to note that track width is not the sole determinant of traction and stability. Related concepts such as track length, pitch, height, and link design also influence these factors. For instance, a longer track will provide more contact area, but it may also increase the vehicle’s turning radius. Similarly, track pitch and link design can affect the vehicle’s ride quality and durability.

Understanding the significance of track width and its interplay with other track dimensions is crucial for optimizing the performance and safety of tracked vehicles. By carefully considering these factors, engineers and designers can create vehicles that excel in specific off-road environments.

Track Pitch: The Unsung Hero of Ride Quality and Durability

In the world of tracked vehicles, the track pitch plays a pivotal role that often goes unnoticed. It might seem like an inconsequential detail, but trust me, this seemingly minor dimension has a profound impact on how your vehicle behaves on the ground.

Pitch Perfect: A Symphony of Smoothness

Imagine rolling over a rough terrain in a tracked vehicle. The track pitch, which refers to the distance between the centers of consecutive track links, acts as a natural shock absorber. A longer pitch allows the track to conform better to uneven surfaces, resulting in a smoother ride. It’s like having an invisible cushion beneath your wheels, damping out those pesky bumps and vibrations.

Durability: The Key to Longevity

On the other hand, a shorter pitch offers increased durability. With links closer together, the track distributes the vehicle’s weight more evenly, reducing the impact on individual components. This is especially crucial in demanding environments, where constant stress and strain can take their toll. Think of it as having a reinforced chassis that can withstand the rigors of off-road adventures.

Balancing Act: Harmony in Pitch

The choice of track pitch is a delicate balancing act. A long pitch might compromise durability, while a short pitch could sacrifice ride quality. But don’t fret! Engineers have meticulously designed tracks with varying pitches to cater to specific applications. A long pitch for comfort-oriented vehicles and a short pitch for heavy-duty workhorses.

Related Harmony: A Symphony of Components

The track pitch doesn’t work in isolation. It’s part of a harmonious ensemble that includes gauge, height, and link design. These dimensions collectively determine the overall performance and characteristics of the track. By carefully selecting the right balance, manufacturers create vehicles that excel in their intended roles.

Whether you’re navigating rocky trails or hauling heavy loads, the track pitch is an essential parameter that should not be overlooked. By understanding its impact on ride quality and durability, you can make informed decisions when choosing or maintaining your tracked vehicle. Remember, it’s all about finding the pitch-perfect harmony that suits your needs and ensures a smooth and reliable journey.

Track Gauge: Crucially Important for Performance and Safety

Within the intricate network of components that make up a vehicle’s undercarriage, track gauge plays a paramount role in its performance and safety. This pivotal dimension ensures a snug fit and facilitates precise steering control, ultimately enhancing the driving experience.

A Closer Look at Track Gauge:

Track gauge refers to the distance between the inner edges of the left and right tracks. It is a critical factor that determines whether a vehicle stands firmly and securely on its wheels or veers off-course dangerously. An insufficient track gauge can compromise stability, leading to a potential loss of control, while an excessive gauge can hinder steering response and reduce maneuverability.

Interdependence with Other Track Dimensions:

Track gauge is intricately linked to other track dimensions, such as track length, width, pitch, and link design. Adjustment in one dimension inevitably impacts the others, necessitating careful consideration of their interplay. For instance, a wider track gauge enhances stability but demands longer tracks and may necessitate changes in link design.

Specific Use Cases:

In specialized applications like construction or agriculture, track gauge is even more crucial. Vehicles operating in rugged terrain require a wider track gauge to ensure stability and prevent bogging down. Conversely, vehicles designed for high-speed travel often opt for a narrower track gauge for enhanced maneuverability.

Monitoring Track Gauge:

Maintaining the appropriate track gauge is essential for optimal performance. Regular checks of this dimension are highly recommended, especially after major repairs or overhauls. Deviations from the specified track gauge can be indicators of underlying issues that need prompt attention.

Track gauge, often overlooked but undeniably pivotal, is an unsung hero in a vehicle’s suspension system. It ensures proper fit and steering control, providing the foundation for safe and confident driving. By understanding the significance of track gauge and its relationship with other track dimensions, drivers can appreciate the intricate engineering that keeps them safe and on track.

Track Height: The Key to Ground Clearance and Obstacle-Crossing Prowess

In the realm of tracked vehicles, track height plays a crucial role in determining their ability to navigate challenging terrain and overcome obstacles. By elevating the vehicle’s frame, it provides ample ground clearance, enabling it to traverse uneven surfaces without getting hung up.

The Importance of High Track Height

Off-road vehicles, such as tanks and construction equipment, often require high track heights to tackle rugged landscapes. The added clearance allows them to roll over fallen logs, climb steep inclines, and ford rivers without difficulty. It also provides a better obstacle-crossing capability, ensuring that the vehicle can overcome obstacles without getting stuck.

Influence on Track Performance

However, track height also affects other aspects of track performance. Longer tracks with greater height tend to have higher rolling resistance, which can increase fuel consumption and reduce speed on paved surfaces. Additionally, high track height can alter the vehicle’s center of gravity, making it more susceptible to tipping over in certain situations.

Optimizing Track Height

Balancing the need for ground clearance and track performance is essential. Manufacturers carefully consider the intended use and terrain conditions when designing the track height of their vehicles. Shorter tracks with lower height provide better stability and fuel efficiency, while taller tracks with higher height offer superior off-road capabilities.

Related Considerations

When discussing track height, it’s important to consider its impact on other track dimensions. Track length, width, pitch, and link design all play a role in determining the overall performance and functionality of the vehicle.

By understanding the significance of track height and its relationship with other track dimensions, manufacturers can optimize the performance of tracked vehicles for specific applications and terrains. From towering over obstacles in war zones to navigating muddy construction sites, track height empowers these vehicles to conquer challenging environments with ease.

Number of Track Links: A Balancing Act for Suspension and Wear

The number of track links on a vehicle plays a crucial role in its suspension performance and wear. Understanding the influence of track link count is essential for optimizing vehicle dynamics and longevity.

A higher number of track links provides greater ground contact area, improving traction and stability. However, it can also increase the rolling resistance, making the vehicle less efficient and responsive. Conversely, a lower number of track links reduces ground contact area, potentially compromising traction and stability, but it also decreases rolling resistance, improving speed and fuel economy.

The pitch of the track, or the distance between track links, also affects the number of links. A longer pitch allows for fewer links while a shorter pitch typically requires more links to maintain the same track length. Longer pitch improves ride quality and durability by reducing vibration, but it can also increase ground clearance, affecting obstacle-crossing capability. Shorter pitch provides better obstacle-crossing capability and stability, but it can lead to a rougher ride and increased wear on components.

To determine the optimal number of track links, engineers consider factors such as the vehicle’s intended use, terrain conditions, and desired balance between performance and durability. For high-performance off-road vehicles, a lower number of track links with a longer pitch might be preferable to maximize traction and stability. In contrast, vehicles designed for smoother terrain or higher speeds may benefit from a higher number of track links with a shorter pitch to enhance ride quality and reduce rolling resistance.

Regular maintenance is crucial for extending the life of track links. Proper track tension ensures the appropriate amount of slack in the track to prevent excessive wear. Worn track links can lead to reduced performance, increased vibration, and safety concerns. Therefore, it’s essential to inspect track links regularly and replace them as needed to maintain optimal vehicle performance and safety.

Link Type and Its Impact on Track Performance

When it comes to track performance, the type of track links you choose plays a crucial role. Different link designs offer a range of benefits and drawbacks, affecting the vehicle’s durability, traction, and rolling resistance.

Durability

The shape and material of the track links impact their resistance to wear and tear. Some links, like forged links, are known for their exceptional strength and durability, while cast links may be more susceptible to breakage. The thickness and hardness of the links also contribute to their lifespan.

Traction

The design of the track links influences the vehicle’s traction. Links with aggressive tread patterns provide better grip on rough terrain, while smooth links offer reduced rolling resistance. The width and shape of the track links also affect the vehicle’s ability to navigate different surfaces.

Rolling Resistance

The rolling resistance of a track is an important factor in determining the vehicle’s fuel efficiency. Links with low profiles reduce resistance, while high profiles increase it. The material of the links also impacts rolling resistance, with steel links typically having higher resistance than rubber links.

Additional Considerations

When choosing track links, consider the following related concepts:

- Length: Longer links provide increased ground contact area but may also reduce maneuverability.

- Width: Wider links offer greater stability but can increase rolling resistance.

- Pitch: The pitch of the links affects ride quality and durability.

- Gauge: The gauge of the links ensures proper fit on the vehicle.

- Height: The height of the links influences ground clearance and obstacle-crossing capability.

By carefully considering the type of track links and their impact on performance, you can optimize your vehicle for your specific needs. Whether you prioritize durability, traction, or rolling resistance, there is a track link design that will meet your requirements.

Track Tension: The Key to a Smooth and Long-Lasting Track System

In the world of tracked vehicles, track tension plays a crucial role in ensuring optimal performance and minimizing wear and tear. Just like the strings on a guitar, proper track tension is essential for a well-tuned machine.

Importance of Track Tension

Maintaining the correct track tension is vital for several reasons. First and foremost, it ensures that the track is properly engaged with the drive sprocket, allowing for efficient power transfer and smooth operation. Additionally, adequate tension prevents the track from skipping or derailing, reducing the risk of accidents and costly repairs.

Consequences of Improper Track Tension

Neglecting track tension can lead to a myriad of problems. If the track is too loose, it can slip off the sprocket, resulting in loss of traction and potential safety hazards. Conversely, if the track is too tight, it can put excessive strain on the suspension components and accelerate wear.

Checking and Adjusting Track Tension

Regularly checking and adjusting track tension is essential for maintaining the health of your tracked vehicle. This process typically involves using a track tension gauge to measure the force required to move the track. The manufacturer’s recommended tension values should be followed to achieve optimal performance.

Signs of Worn or Damaged Tracks

Over time, even with proper maintenance, tracks will naturally wear and deteriorate. Signs of worn or damaged tracks include:

- Cracks or tears in the tracks

- Excessive elongation or stretching

- Broken or missing track links

- Loose or worn pins and bushings

Regular Maintenance and Inspection

To extend the life of your tracks and ensure safe operation, follow these maintenance tips:

- Inspect tracks regularly for signs of damage

- Clean and lubricate tracks according to manufacturer’s recommendations

- Check and adjust track tension as needed

- Replace worn or damaged tracks promptly

By paying attention to track tension and following these maintenance practices, you can ensure that your tracked vehicle operates smoothly, efficiently, and safely for many years to come.

Track Wear: The Natural Deterioration of Tracks

As tracks traverse countless terrains and endure demanding conditions, they inevitably wear over time. Understanding the natural deterioration of tracks is crucial for maintaining optimal vehicle performance and ensuring safety.

Causes and Types of Track Wear

The gradual degradation of tracks results from various factors, including:

- Abrasion: Repeated contact with rough surfaces leads to the erosion of track components.

- Fatigue: Continuous stress and strain can cause cracks and fractures in track links.

- Corrosion: Exposure to moisture and corrosive elements weakens track materials.

Depending on the type of track and operating environment, different types of wear may occur:

- Uniform wear: Gradual thinning of track components across their entire surface.

- Localized wear: Excessive wear in specific areas, such as the tips of track links or the edges of guide horns.

- Severe wear: Rapid or catastrophic deterioration of track components, often due to extreme conditions or lack of maintenance.

Consequences of Track Wear

Worn tracks can significantly impact vehicle performance and safety:

- Reduced traction: Diminished ground contact area and compromised tread patterns reduce grip.

- Increased rolling resistance: Worn tracks increase the force required to move the vehicle, leading to reduced efficiency and fuel consumption.

- Unstable steering: Excessive wear can affect track alignment, resulting in poor handling and reduced maneuverability.

- Suspension damage: Worn tracks can compromise suspension performance, leading to a rougher ride and increased wear on other components.

- Safety hazards: Severely worn tracks pose a safety risk, increasing the likelihood of track failures that can cause derailments or other accidents.

Monitoring and Mitigation of Track Wear

To mitigate the effects of track wear, regular monitoring and maintenance are essential:

- Visual inspections: Periodic examinations can detect early signs of wear and identify areas that require attention.

- Measurement tools: Specialized gauges and ultrasonic devices can accurately measure wear and track tension.

- Proper maintenance: Regular lubrication, cleaning, and adjustment help extend track lifespan and prevent premature wear.

By understanding the causes, consequences, and mitigation strategies for track wear, you can ensure optimal vehicle performance, maintain safety, and extend the lifespan of your tracks.