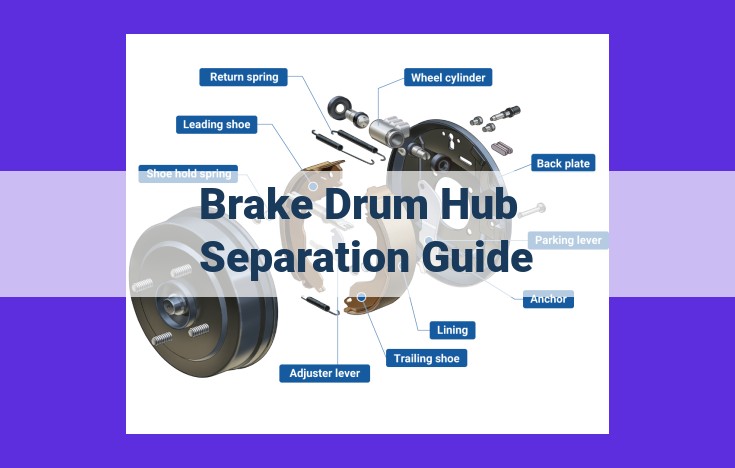

A brake drum hub separation guide assists in safely and effectively separating the brake drum from the hub in brake assemblies. Composed of a brake drum, hub, brake shoe, brake lining, and caliper, these assemblies require proper separation for maintenance and performance optimization. Using a separation guide ensures accuracy, safety, and efficiency during the process. By following a step-by-step guide, technicians can ensure proper hub separation, maximizing brake performance and maintaining vehicle safety.

Understanding the Importance of Brake Drum Hub Separation

In the intricate world of automotive maintenance, ensuring the proper functioning of your vehicle’s braking system is paramount. Among the crucial components of this system is the brake drum, a cylindrical element that rotates with the wheel and houses the brake shoes. The brake shoes, lined with friction material, make contact with the inner surface of the drum to slow down or stop the rotation. The hub, on the other hand, is the central part of the wheel assembly that supports the brake drum and rotates with it.

Proper maintenance of your vehicle’s braking system involves separating the brake drum from the hub. This separation process allows for inspection, repair, or replacement of either component. A brake drum hub separation guide is an essential tool that facilitates this process. It provides safe and efficient separation without damaging the components.

Benefits of Using a Brake Drum Hub Separation Guide:

- Safety: The guide ensures a controlled separation, preventing any sudden release of tension or flying parts.

- Efficiency: The guide’s design enables a quicker and easier separation, saving time and effort.

- Accuracy: The guide aligns the components precisely, ensuring a proper and even separation.

Step-by-Step Guide to Using a Brake Drum Hub Separation Guide:

- Safety First: Wear appropriate safety gear and use a stable work surface.

- Identify Screw Locations: Locate the screws that attach the brake drum to the hub.

- Insert Guide: Slide the brake drum hub separation guide into the gap between the drum and the hub.

- Tighten Screws: Gradually tighten the screws using a torque wrench to the specified torque.

- Separate: As the screws tighten, the brake drum will gradually separate from the hub. Use caution and support the drum as it comes loose.

Proper separation of the brake drum and hub is crucial for maintaining a safe and reliable braking system. By utilizing a brake drum hub separation guide, you can ensure efficient and accurate separation, contributing to the overall safety and performance of your vehicle. Remember, if you encounter any difficulties or have concerns, always seek professional guidance from a qualified mechanic.

The Key Players in Your Vehicle’s Braking System: Understanding the Components of a Brake Assembly

The brake assembly in your vehicle plays a crucial role in ensuring your safety on the road. At its core lie several essential components that work together in harmony to bring your car to a safe and controlled stop. Let’s dive into the functions of the brake drum, hub, and related components:

The Brake Drum: The Rotating Foundation

The brake drum serves as the rotating foundation of the assembly. It’s typically made of cast iron or aluminum and is mounted on the wheel hub. As the wheel rotates, so does the brake drum.

The Wheel Hub: Anchoring the Wheel

The wheel hub is the stationary component that connects the wheel to the axle. It houses the wheel bearings, which allow the wheel to rotate smoothly while supporting the weight of the vehicle.

The Brake Shoes: The Friction-Creating Pads

Brake shoes are semi-circular pads lined with brake lining. They are mounted inside the brake drum. When the brake pedal is pressed, the shoes press against the inner surface of the drum, creating friction and slowing down the rotation of the wheel.

The Brake Lining: The Abrasive Surface

The brake lining is the friction material that makes contact with the brake drum. It’s typically made of a composite material that generates high levels of friction when applied against the drum.

The Brake Caliper: The Force Multiplier

In disc brake systems, the brake caliper replaces the brake shoe. It houses the brake pads, which are pressed against the rotating brake rotor by hydraulic pressure. This pressure amplification provides increased braking force.

Understanding the Critical Relationship between Components

The performance of the entire brake assembly relies on the seamless interaction of each component. The brake drum and hub provide the rotating and static surfaces, while the brake shoes or pads and lining generate the necessary friction for stopping. The brake caliper (in disc brake systems) or the hydraulic pressure in drum brake systems multiplies the force applied to the brakes, ensuring effective braking.

By fully understanding the functions of these components, you can appreciate the complexity and importance of your vehicle’s braking system, enabling you to make informed decisions about its maintenance and repair.

Importance of Separating Brake Drum and Hub

Maintaining a well-functioning braking system is crucial for vehicle safety. Regular maintenance, such as separating the brake drum from the hub, ensures optimal performance and prevents costly repairs.

The brake drum and hub are essential components of a brake assembly. The brake drum rotates with the wheel, while the hub is attached to the axle. When you apply the brakes, the brake shoes inside the drum press against its surface, creating friction to slow down the wheel.

Separation of the brake drum from the hub is vital for several reasons. Improper separation can lead to difficulties in accessing the brake components for maintenance, such as replacing brake shoes or inspecting the brake lining.

Moreover, improper separation can compromise the performance of the brakes. If the brake drum is not properly separated from the hub, it can warp or bend due to the heat generated during braking. This can cause uneven wear on the brake shoes and lead to reduced braking efficiency.

In severe cases, improper separation can cause the brake drum to seize on the hub, resulting in a total loss of braking ability. This can be extremely dangerous and should be avoided by ensuring proper separation during maintenance.

By separating the brake drum from the hub, you can maintain easy access to the brake components, ensuring efficient maintenance. It also helps prevent warping or bending of the brake drum, ensuring optimal braking performance.

Understanding the Separation Process

In the intricate symphony of a vehicle’s braking system, the separation of the brake drum from the hub is a crucial step, often overlooked but essential for ensuring the car’s safety and performance.

The brake drum is a cylindrical component that rotates with the wheel, while the hub is the stationary center that provides support and attachment to the wheel assembly. When it comes time to service or replace the brake shoes or other components within the drum, separation is the act of disassembling these two parts to expose the inner workings.

Why is Separation Important?

Separating the brake drum from the hub is paramount for several reasons:

- Access: The brake shoes, lining, and other components are concealed within the brake drum. Separation allows clear access for inspection, cleaning, or replacement.

- Maintenance: Regular separation is essential for proper brake maintenance, as it enables the removal of corrosion, debris, or any potential hindrances that may impair brake performance.

- Performance: Neglecting separation can lead to reduced braking efficiency, increased wear and tear on brake components, and even premature failure, compromising the vehicle’s safety.

**Unlocking the Secrets of Brake Drum Hub Separation Guides: A Guide to Enhanced Safety, Efficiency, and Accuracy**

When it comes to maintaining your vehicle’s braking system, the brake drum hub separation guide is an essential tool that can significantly enhance your safety, efficiency, and accuracy.

Safety First: Preventing Mishaps and Injuries

The brake drum hub is a heavy component that requires careful handling. Attempting to separate it with brute force or improper tools can lead to accidents like slips and falls. A separation guide provides a safe and controlled method for removing the drum without straining your muscles or risking injury.

Efficiency for Faster Maintenance

Traditional methods of prying open the drum can be time-consuming and tiring. A separation guide makes it a breeze, allowing you to separate the hub from the drum effortlessly. This efficiency translates to faster maintenance and reduced downtime for your vehicle.

Accuracy for Precision

Improper separation can damage the brake assembly, affecting its performance. The separation guide ensures that the drum is removed without causing any damage to the brake lining, brake shoe, or caliper. This precision ensures that your braking system functions optimally, providing you with peace of mind and a safer driving experience.

Step-by-Step Guide to Using a Brake Drum Hub Separation Guide

Prepare and Gather:

Before embarking on this task, ensure your safety by wearing appropriate protective gear and gathering the necessary tools, including your brake drum hub separation guide and a sturdy wrench or socket set. Park your vehicle on level ground and engage the parking brake for added stability.

Locate the Adjusting Hole:

Identify the adjusting hole located on the back of the brake drum. This hole provides access to the brake shoes and allows for adjustment and removal. Clean the area around the hole thoroughly to prevent dirt from entering the braking system.

Insert the Separation Guide:

Carefully insert the separation guide into the adjusting hole. The guide should fit snugly without any excessive movement. Apply pressure to the guide to force the brake shoes apart, gradually separating the brake drum from the hub.

Monitor the Brake Shoes:

As you continue to apply pressure, monitor the brake shoes. They should gradually move away from the brake drum, creating enough clearance to remove the drum. If the shoes get stuck, use a small screwdriver or pick tool to gently pry them apart.

Inspect and Clean:

Once the brake drum is fully separated, inspect the shoes and the hub for any signs of wear or damage. Remove any dirt or debris that may have accumulated. Use a wire brush or compressed air to clean the guide and the area around the hub thoroughly.

Troubleshooting:

If you encounter any resistance during the separation process, stop immediately and troubleshoot the issue. Check if the parking brake is disengaged. Ensure the separation guide is inserted correctly and that it fits snugly. If the shoes are stuck, use a penetrating lubricant to loosen them up. Seek professional assistance if the issue persists.

Reassembly:

Once the brake drum hub is separated, you can perform the necessary repairs or maintenance. After completing the work, reassembly is crucial. Carefully align the brake drum with the hub and slide it into place. Use the separation guide to press the brake shoes back into position. Tighten the lug nuts to the specified torque and reattach the wheel.

Safety Precautions:

Always wear proper protective gear when working on your vehicle. Never work on a vehicle that is supported by only a jack or jack stands. Use a sturdy jack and multiple jack stands to ensure stability. Do not attempt this task if you are uncomfortable or unfamiliar with automotive repair.