- **Understanding Mates**: Mates connect components, defining their relative positions and orientations. Hinges require mates with rotational axes.

- **Creating a Hinge**: Create a mate plane, sketch the hinge, define the axis of rotation, select the joint type (e.g., hinge), set hinge limits, and apply mate properties.

- **Related Concepts**: Axis types, mate connectors, hinge limits, and advanced mate properties enhance hinge functionality.

Understanding Mates: The Cornerstones of Hinges

In the realm of product design, hinges play a pivotal role, connecting components and allowing for seamless movement. To create hinges that are both functional and aesthetically pleasing, it’s essential to have a firm grasp of the fundamental concept of mates. Mates are the building blocks that define the relationship between different components within an assembly. They act as virtual connectors, dictating how parts move and interact with each other.

At the heart of every mate lies an axis of rotation, an invisible line that defines the direction along which a component can rotate. The mate connectors, on the other hand, represent the points that connect the different components. They ensure that the components move in sync, preventing any undesired displacement.

Mate properties further refine the behavior of mates. These properties allow you to control aspects such as the range of motion, the stiffness of the connection, and the damping factor. By fine-tuning these properties, you can achieve hinges that exhibit the precise motion and feel you desire.

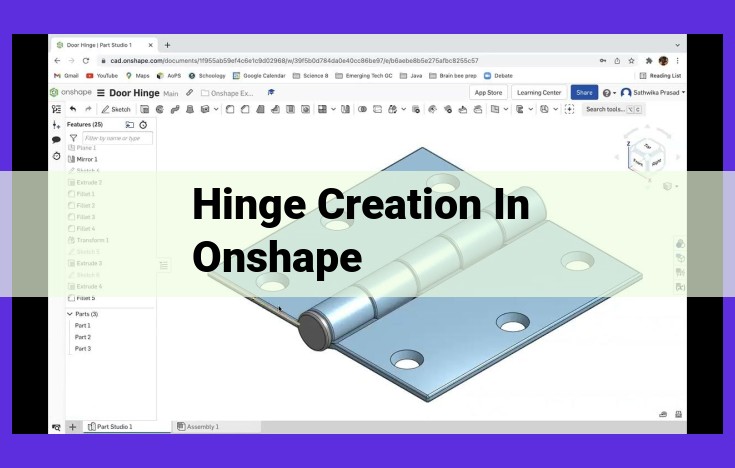

Creating a Hinge in Onshape: A Step-by-Step Guide

Mastering the art of 3D modeling requires a deep understanding of mates, the fundamental tools that allow components to interact within an assembly. Hinges are a critical element in many designs, enabling articulated movement and adding functionality to your creations. In this step-by-step guide, we’ll explore the process of creating a hinge in Onshape, empowering you to design effective and visually appealing mechanisms.

Step 1: Creating a Mate Plane

The first step is to prepare a mate plane, which serves as a reference surface for aligning the hinge components. Select the surface where the hinge will be attached and create a mate plane by right-clicking and choosing “Insert Mate Plane.”

Step 2: Sketching the Hinge

Next, it’s time to sketch the outline of the hinge. Use the sketching tools to draw the geometry of the hinge components, considering the desired shape and size. Ensure the sketches are aligned with the mate plane created earlier.

Step 3: Defining the Axis of Rotation

The axis of rotation determines the direction in which the hinge will rotate. Select the edge or line that will act as the axis and create a point on that element. Right-click and choose “Insert Axis.”

Step 4: Selecting the Joint Type

Onshape offers various joint types for hinges, including cylindrical, spherical, and planar. Choose the joint type that best suits the desired functionality of the hinge. For a basic hinge, a cylindrical joint is a common choice.

Step 5: Setting Hinge Limits

In many cases, you’ll want to limit the range of motion for the hinge. Use the “Hinge Properties” dialog to specify the minimum and maximum angles for rotation. This ensures that the hinge operates within the desired constraints.

Step 6: Applying Mate Properties

Finally, define the mate properties to control how the hinge components interact. Adjust the clearances, interference, and stiffness to achieve the desired motion and stability. Additionally, you can specify whether the hinge should be driven (allowing manual rotation) or locked to prevent movement.

By following these steps, you can confidently create hinges in Onshape that are both functional and visually appealing. Experiment with different joint types, axis of rotations, and hinge limits to expand your design possibilities. Embrace the power of mates and bring your hinges to life in the world of 3D modeling.

Exploring Related Concepts for Hinge Creation

As we delve deeper into the realm of hinge creation, let’s unveil some related concepts that will empower you to craft flawless hinges.

Axis Types

The axis of rotation is the “backbone” of your hinge. It determines how your hinge moves and rotates. Onshape offers various axis types to suit different hinge designs:

- Coincident axis: Aligns with the direction of a line or surface.

- Parallel axis: Runs parallel to a line or surface.

- Perpendicular axis: Intersects a line or surface at a 90-degree angle.

Mate Connectors

Mate connectors are the “meeting points” of two parts in a hinge. They define the exact location where rotation occurs. Onshape provides different mate connector options:

- Point-to-point: Connects two points on different parts.

- Line-to-line: Connects two lines on different parts.

- Plane-to-plane: Connects two planes on different parts.

Hinge Limits

Hinge limits define the rotational range of your hinge. You can restrict rotation to a specific angle range, preventing over-extension or damage.

Advanced Mate Properties

Advanced mate properties allow for fine-tuning the behavior of your hinge. These include:

- Stiffness: Controls the resistance to rotation.

- Damping: Determines how quickly the hinge returns to its starting position.

- Friction: Affects the amount of resistance experienced during rotation.

Tips for Designing Effective Hinges

Craft Hinges for Seamless Performance:

When designing hinges, functionality and aesthetics go hand in hand. Plan hinges that pivot smoothly, withstand stress, and enhance the overall appeal of your designs. Here are some expert tips to guide you:

1. Consider Load and Movement Requirements:

Understand the intended load and movement range of the hinge. Select materials and dimensions accordingly to ensure durability under varying conditions.

2. Optimize Axis Placement:

The axis of rotation plays a crucial role in hinge performance. Place it strategically to minimize friction and maximize stability.

3. Explore Joint Types:

Onshape offers various joint types, each with unique characteristics. Consider pin, socket, and slider joints based on the desired range of motion and load requirements.

4. Define Hinge Limits (if necessary):

Set maximum and minimum angles for hinges that need to be restricted within a specific range of motion. This prevents overextension and damage.

5. Utilize Mate Properties:

Mate properties such as friction and damping can fine-tune hinge behavior. Adjust these settings to achieve the desired smoothness and responsiveness.

6. Pay Attention to Aesthetics:

Hinges can also serve as decorative elements. Consider their shape, size, and finish to complement the overall design aesthetic.

7. Test and Iterate:

Create prototypes and test the hinges under real-world conditions. Iterate on the design to optimize performance and ensure a visually appealing end product.

Troubleshooting Common Hinge Issues in Onshape

When designing and implementing hinges in your Onshape models, you may occasionally encounter challenges. Here, we’ll address some frequent issues and provide strategies to help you navigate them effectively.

Hinge Not Moving as Expected

If your hinge is not operating smoothly or as intended, there are a few potential causes to consider:

- Incorrect Axis of Rotation: Verify that you have defined the correct axis of rotation for the hinge. This axis determines the direction of movement for the hinge parts.

- Insufficient Hinge Limits: Ensure that you have set appropriate hinge limits to prevent excessive rotation or over-extension.

- Mate Connectors Misaligned: Check if the mate connectors on the hinge parts are properly aligned. Misalignment can hinder the hinge’s range of motion.

Hinge Binding or Sticking

Binding or sticking of the hinge may occur due to several factors:

- Interference Between Parts: Examine if there is any physical interference between the hinge parts or adjacent components. This can restrict the movement of the hinge.

- Excessive Friction: Check for excessive friction between the hinge components. Lubrication or material adjustments may be necessary to reduce friction and improve movement.

- Incorrect Mate Properties: Review the mate properties applied to the hinge. Inappropriate settings, such as excessive damping, can result in binding or sticking.

Hinge Wobbly or Loose

Wobbliness or looseness in the hinge may arise due to several reasons:

- Insufficient Mate Strength: Check the strength of the mates applied to the hinge. Weak mates can lead to instability and wobbling.

- Loose or Worn Components: Inspect the hinge components for any loose fasteners or worn pins. Tightening or replacing worn parts can enhance stability.

- Improper Hinge Design: Consider if the hinge is designed appropriately for the intended use. Factors such as hinge size, shape, and material choice can affect its stability.

By addressing these common issues and implementing the suggested solutions, you can ensure that your hinges in Onshape perform seamlessly and contribute to the optimal functionality of your designs.