Hot mop roofing, a durable and affordable roofing method, involves applying hot asphalt to multiple layers of felt paper. The primary material, asphalt, provides water resistance and adhesion, while felt provides support and helps create a watertight barrier. Mastic, an adhesive, bonds the felt layers together. Essential tools include mops for applying asphalt, shovels for spreading it, and rakes for smoothing. Gravel, added for protection against elements, enhances the roofing system’s performance. Understanding these concepts is crucial for installing and maintaining hot mop roofing.

Delving into the World of Hot Mop Roofing: A Comprehensive Guide

Hot mop roofing, a time-tested roofing technique, has stood the test of time thanks to its durability and effectiveness. In this comprehensive guide, we’ll unravel the intricacies of hot mop roofing, exploring its definition, benefits, and the key materials involved in its construction.

Understanding Hot Mop Roofing

Hot mop roofing is a meticulously applied roofing system that involves the meticulous application of hot asphalt to multiple layers of felt paper. This unique combination of materials creates a robust roofing system that offers exceptional protection from the elements.

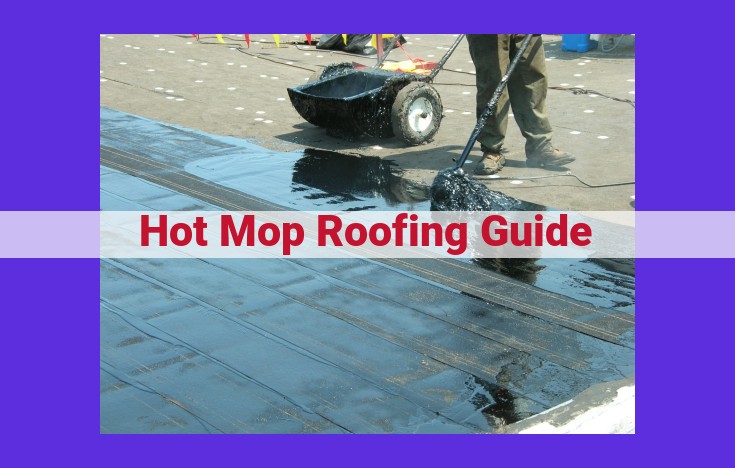

The process begins with the installation of felt paper, which supports the asphalt layers and creates a watertight barrier. Hot asphalt is then applied using a mop, bonding the felt layers together and sealing the roof’s surface.

Benefits and Applications

Hot mop roofing boasts an impressive array of benefits, including:

- Durability: Hot mop roofs are renowned for their exceptional longevity, withstanding harsh weather conditions and lasting for several decades.

- Weather Resistance: The seamless asphalt layer provides excellent protection against rain, snow, and wind, effectively guarding against leaks.

- Affordability: Compared to other roofing systems, hot mop roofing is a relatively cost-effective option, making it a popular choice for commercial and residential properties alike.

Materials and Tools

The success of hot mop roofing relies on the quality of its materials:

- Asphalt: The primary component of hot mop roofing, asphalt is a viscous material that adheres strongly to felt paper, creating a watertight seal.

- Felt Paper: A strong, flexible material, felt paper provides support and reinforcement for the asphalt layers, preventing tearing and punctures.

- Mastic: A specialized adhesive, mastic bonds the felt layers together, ensuring the roof’s integrity and durability.

Essential tools facilitate the installation process:

- Mops: Mops are used to apply hot asphalt, ensuring an even distribution and optimal adhesion.

- Shovels: Shovels are employed to spread the asphalt, ensuring a uniform thickness and smooth surface.

- Rakes: Rakes are used to level the asphalt and create a seamless finish, enhancing the roof’s aesthetics and performance.

The Finishing Touch: Gravel

A final layer of gravel adds the finishing touch to a hot mop roof, providing:

- UV Protection: Gravel shields the asphalt from harmful UV rays, preventing premature aging and extending the roof’s lifespan.

- Puncture Resistance: The gravel layer acts as a protective barrier, reducing the risk of punctures and other damage.

- Fire Resistance: Gravel inhibits the spread of fire, increasing the roof’s safety and reducing fire hazards.

Hot mop roofing remains a popular choice due to its durability, weather resistance, and affordability. By understanding the key concepts and materials involved in this roofing system, you can make informed decisions about the best roofing solution for your property. Whether you’re a homeowner, contractor, or property manager, this guide will provide you with the essential knowledge to confidently navigate the world of hot mop roofing.

Benefits and Versatile Applications of Hot Mop Roofing

Hot mop roofing has gained prominence due to its remarkable advantages and wide-ranging applications. This time-honored technique offers a host of benefits that set it apart from other roofing systems.

Exceptional Durability: Hot mop roofing reigns supreme in terms of longevity. The multiple layers of asphalt and felt intertwine like a steadfast shield, providing unparalleled resistance to the elements. This durable construction withstands the test of time, promising many years of reliable protection.

Unwavering Weather Resistance: Hot mop roofing emerges as an unwavering sentinel against Mother Nature’s wrath. Its impervious barrier effectively sheds water, preventing leaks and moisture penetration. Even in the face of torrential downpours, hail, and relentless winds, hot mop roofing remains unyielding, ensuring the integrity of your structure.

Remarkable Affordability: Hot mop roofing stands out as an economical choice, offering exceptional value for your money. Compared to other roofing systems, its lower material and installation costs make it an attractive option for budget-conscious homeowners and businesses alike. While its affordability is undeniable, it doesn’t compromise on quality, providing a cost-effective solution for long-lasting protection.

Diverse Applications: Hot mop roofing proves its versatility by gracing a wide range of structures. From towering commercial buildings to sprawling industrial complexes, its robust nature makes it an ideal choice for high-traffic areas and facilities demanding durability. Residential homes also benefit from its protective embrace, ensuring a secure and dry haven for families.

Asphalt: The Bedrock of Hot Mop Roofing

Asphalt, a natural and versatile material, forms the backbone of hot mop roofing. This ancient substance, born from the depths of the earth, has been utilized for centuries as a roofing material due to its exceptional properties.

Asphalt’s viscosity, which determines its thickness and flowability, plays a crucial role in hot mop roofing. When heated, asphalt transforms into a thick, molten liquid that can be easily applied to the roof. As it cools, it solidifies, creating a durable and watertight barrier.

Melting Point is another key characteristic of asphalt. The high melting point of asphalt ensures that it remains solid under normal conditions, withstanding the harsh elements and the scorching sun.

Adhesion is paramount in hot mop roofing. Asphalt’s ability to adhere strongly to other materials, such as felt and gravel, is essential for creating a cohesive and long-lasting roofing system. This adhesion prevents leaks and ensures the integrity of the roof.

The unique combination of these properties makes asphalt the ideal choice for hot mop roofing, a time-tested and reliable roofing method that has withstood the test of time.

Felt: The Supporting Layer in Hot Mop Roofing

In the realm of hot mop roofing, where durability and longevity reign supreme, the unsung hero is undoubtedly felt paper. This remarkable material, composed primarily of cellulose fibers, plays a pivotal role in providing structural integrity and water resistance to these time-tested roofing systems.

Felt paper is imbued with a unique combination of properties that make it ideally suited for this demanding application. Its high tensile strength enables it to bear the weight of multiple layers of asphalt, while its porous nature allows the asphalt to penetrate and form a watertight bond. This symbiotic relationship between felt and asphalt creates a resilient barrier that effectively shields buildings from the elements.

Beyond its structural role, felt paper also serves as a separator between the asphalt layers. This separation prevents the layers from sticking together and allows for expansion and contraction due to temperature fluctuations. This flexibility ensures that the roofing system can withstand the rigors of changing weather conditions without compromising its integrity.

In essence, felt paper is the silent partner in hot mop roofing, providing indispensable support and protection. Its presence guarantees a durable, watertight roof that stands the test of time, safeguarding buildings and ensuring peace of mind.

Mastic: The Adhesive that Binds the Hot Mop Roofing Together

In the world of hot mop roofing, the adhesive known as mastic plays a crucial role in binding the layers of felt together into an impenetrable shield. This remarkable substance is the glue that holds the roofing system together, ensuring its resilience against the elements.

There are two main types of mastic used in hot mop roofing:

- Asphalt-based mastic: This is the more traditional type of mastic, made from a blend of asphalt and mineral fillers. It provides excellent adhesion and durability, making it a popular choice for a variety of roofing applications.

- Butyl-based mastic: A newer type of mastic, butyl-based mastic offers improved flexibility and resistance to weather extremes. It is often used in areas with extreme weather conditions or on roofs with complex shapes.

Composition and Role of Mastic

Mastic is typically composed of a combination of polymers, resins, and solvents. The polymers provide the adhesive properties, while the resins enhance the cohesive strength and flexibility of the mastic. The solvents allow the mastic to be applied easily and evenly.

In hot mop roofing, mastic is applied between each layer of felt paper, creating a strong bond that resists tearing and splitting. The adhesive properties of mastic ensure that the layers of felt form a continuous, watertight barrier, protecting the roof from moisture infiltration and external damage. Additionally, mastic helps to distribute stresses evenly across the roofing system, preventing premature wear and tear.

Properly applied mastic is essential for the longevity and performance of a hot mop roof. Its adhesive qualities create a secure bond that withstands the fluctuations of temperature and weather conditions, ensuring that the roof remains intact over time.

Tools of the Trade: Essential Implements for Hot Mop Roofing

Introduction:

In the realm of roofing, the hot mop roofing method stands out as an enduring and reliable solution. It requires a skilled touch and meticulous craftsmanship to execute effectively. Among the essential tools that make this process possible are the mop, shovel, and rake—each playing a vital role in ensuring a successful installation.

The Mop: Applying the Asphalt Canvas

The mop is the primary instrument for applying the molten asphalt to the roofing surface. Made of a sturdy wooden handle and a wide, absorbent head, it acts like a brush, spreading the hot asphalt evenly and smoothly. The mop’s head is designed to absorb and retain the heat, allowing for efficient and precise application.

The Shovel: Spreading the Asphalt Uniformly

The shovel is a flat-bladed tool that serves to distribute the asphalt evenly across the roofing surface. Its wide, square shape allows for a generous scoop of asphalt, which is then spread in a controlled manner. The shovel’s sharp edges help to cut through the asphalt, ensuring a uniform thickness and a consistent bond with the felt layers.

The Rake: Smoothing and Finishing the Surface

The rake is the final tool in the hot mop roofing sequence, responsible for smoothing and leveling the asphalt surface. It features a series of teeth or tines that gently scrape and distribute the asphalt, eliminating any imperfections or irregularities. The rake’s flexibility allows it to conform to the contours of the roof, ensuring a smooth, watertight finish.

Significance of Using the Right Tools

Using the correct tools in hot mop roofing is paramount for several reasons. Proper tools:

- Ensure Efficient Application: The right tools, such as a dedicated mop and shovel, allow for efficient and precise application of the asphalt, minimizing waste and ensuring a uniform thickness.

- Guarantee a Strong Bond: The mop’s ability to absorb and retain heat, along with the shovel’s ability to spread the asphalt evenly, helps to create a strong and durable bond between the asphalt and the felt layers.

- Create a Smooth and Waterproof Surface: The rake’s smoothing action removes any imperfections, resulting in a smooth and waterproof surface that protects the roof from the elements.

- Extend the Roof’s Lifespan: Using the correct tools ensures a high-quality installation, extending the roof’s lifespan and maximizing its performance.

Conclusion:

The mop, shovel, and rake are indispensable tools in the art of hot mop roofing. Each tool plays a specific role in applying, distributing, and smoothing the asphalt, ensuring a durable, waterproof, and long-lasting roofing system. Understanding the importance of these tools is essential for anyone involved in the installation or maintenance of hot mop roofing.

Gravel: The Protective Armor of Hot Mop Roofing

In the realm of roofing, hot mop roofing stands out as a durable and weather-resistant solution. This traditional method involves layering felt paper with hot asphalt to create a watertight barrier. However, there’s one additional element that plays a crucial role in the longevity and performance of a hot mop roof – gravel.

Protection from the Sun’s Wrath

As the sun’s relentless rays shower down on a hot mop roof, it can cause the asphalt to soften and deteriorate. This can lead to premature aging and potential leaks. To mitigate this, a layer of gravel is applied to the surface, acting as a protective shield against ultraviolet (UV) damage. The gravel absorbs the sun’s heat, preventing it from reaching and damaging the asphalt beneath.

Defending Against Punctures

Hot mop roofs are often used on industrial and commercial buildings, where the risk of punctures is higher. The gravel topping provides an additional layer of protection against accidental punctures or impacts. Its rough surface helps to deflect objects that could otherwise pierce the roofing membrane, ensuring watertight integrity.

Fire Resistance: A Guardian Against Flames

In the unfortunate event of a fire, hot mop roofing with a gravel topping can provide an extra layer of fire resistance. The gravel acts as a non-combustible barrier, preventing flames from directly reaching the asphalt and spreading throughout the roof. This can buy precious time for occupants to evacuate and for firefighters to extinguish the blaze.

Types of Gravel and Their Impact

The type of gravel used on a hot mop roof can have a significant impact on its performance. Crushed stone is a popular choice due to its durability and resistance to UV damage. Pebbles are another option, offering a smoother aesthetic appearance. The size and quantity of gravel applied will vary depending on the roof’s slope and intended use.

Gravel is an essential component of hot mop roofing, providing protection against UV damage, punctures, and fire. Its durable nature and ability to withstand harsh conditions ensure the longevity and performance of this traditional roofing method. Whether it’s on an industrial complex, commercial building, or residential home, the gravel topping serves as a testament to the time-honored resilience and effectiveness of hot mop roofing.