Hump yards are pivotal in railroad operations, facilitating the sorting of freight cars. Cars are pushed over a “hump” to gain momentum, rolling down classification tracks designated for specific destinations. Controlled by retarders, cars enter tracks via switches. Caboose (if used) provides additional braking power. The yardmaster coordinates humping, track switching, and train assembly. Understanding hump yards illuminates modern railway systems, as they expedite freight transportation by efficiently sorting and assembling trains based on destination.

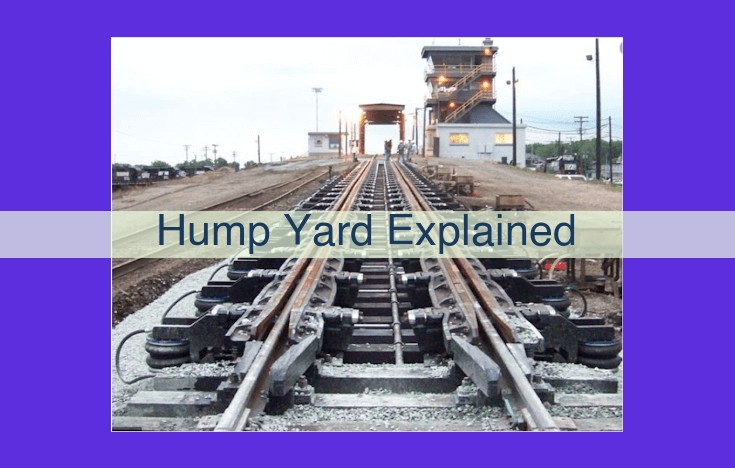

Demystifying Hump Yards: The Unsung Heroes of Freight Rail

In the intricate network of modern railway systems, there exist unsung heroes that play a vital role in the seamless flow of goods: hump yards. These specialized facilities are the gatekeepers of efficient freight car sorting and train assembly, ensuring that countless shipments reach their destinations on time.

Hump yards, as the name suggests, are characterized by a towering hump – a strategically engineered incline – that provides cars with the necessary momentum to roll down and be classified onto their designated tracks. Specialized locomotives push cars over the hump, propelling them towards their predetermined destinations.

Once the cars embark on their descent, they encounter classification tracks – an array of tracks strategically arranged to minimize switching operations. These tracks are meticulously designed to ensure that cars bound for the same destination or type are grouped together.

Ensuring a controlled and safe entry into classification tracks is the role of retarders – devices that apply braking force to the cars as they roll down from the hump. By regulating the speed of the cars, retarders prevent uncontrolled collisions and ensure a smooth transition onto the appropriate tracks.

Guiding the cars onto the correct classification tracks are switches – movable rails that direct the cars’ path. These switches are actuated remotely or manually by skilled operators, ensuring precise flow control and preventing misrouting.

Traditionally, cabooses served as the last line of defense in hump yards, providing additional braking power and serving as crew space. However, modern locomotives have largely replaced cabooses, although some yards still employ them for safety purposes.

Overseeing the intricate dance of humping, track switching, and train assembly is the yardmaster – the conductor of hump yard operations. These individuals possess a deep understanding of the yard’s layout and train schedules, orchestrating a seamless ballet of movement to keep the freight flowing efficiently.

The Hump: The Powerhouse of Momentum

In the vast rail yards where freight trains converge, a towering structure stands out as the epicenter of action: the hump. This strategic incline serves as the powerhouse of momentum, propelling railcars destined for various tracks.

Imagine a long train laden with cars, patiently waiting at the base of the hump. Specialized locomotives, known as hump engines, roar into action, their massive engines straining as they push the cars upward. The crescendo of their engines echoes through the yard, signaling the start of a meticulously orchestrated dance.

As the cars crest the hump’s summit, they gain momentum, rolling towards their designated tracks. This controlled descent is crucial for classification, the process of sorting cars based on their final destinations. The hump’s strategic elevation provides the initial force that sets the cars in motion, ensuring swift and efficient movement throughout the rail yard.

Classification Tracks: Destination Sorting:

- Discuss the purpose of classification tracks in sorting cars based on destination or type.

- Explain how the tracks are strategically arranged to minimize switching operations.

Classification Tracks: The Destination Sorters of Hump Yards

In the heart of a hump yard, a bustling hub of train operations, lies a labyrinth of classification tracks. These tracks, like meticulous organizers, play a pivotal role in sorting and directing freight cars based on their final destinations or types.

Strategically arranged to minimize switching operations, these tracks are designed with precision. Cars are meticulously routed onto specific tracks, ensuring they’re grouped with others bound for the same destinations. This organized approach streamlines the process of assembling trains, allowing them to depart promptly and efficiently.

The classification yard operates like a well-choreographed symphony, with each track serving a specific purpose. One track may be designated for cars destined for the bustling metropolis of Chicago, while another caters to shipments bound for the sprawling warehouses of Los Angeles. By categorizing cars in this manner, the yard reduces the need for multiple switching maneuvers, saving time and resources.

Note: Incorporating relevant imagery, such as a diagram of classification tracks, can enhance the reader’s understanding of the concept.

The Retarder: Ensuring a Controlled Descent in Hump Yards

In the realm of railroad operations, hump yards play a crucial role in sorting and assembling freight cars efficiently. At the heart of these yards lies a critical component – the retarder. This ingenious device plays a pivotal role in controlling the speed of cars as they descend from the hump.

The hump, an elevated track, provides cars with momentum for rolling and classification. However, this velocity can be excessive if left unchecked. The retarder, strategically positioned at the base of the hump, applies braking force to the descending cars. This braking action ensures safe and manageable entry into the designated classification tracks.

Without the precise control offered by retarders, cars would enter the classification tracks at uncontrolled speeds, potentially leading to collisions or derailments. The retarders provide optimized braking power, allowing for smooth and efficient sorting of cars based on their destination or type.

Retarders come in various forms, including hydraulic, pneumatic, and electromagnetic. Each type employs a different mechanism to apply braking force. Hydraulic retarders utilize a fluid-filled cylinder, while pneumatic retarders use compressed air. Electromagnetic retarders, on the other hand, rely on magnetic fields to induce braking.

The yardmaster, the conductor of operations in the hump yard, monitors and adjusts the retarder settings to ensure precise speed control. This fine-tuning of the braking force is crucial for safe and efficient classification of rail cars. By controlling the descent of cars with precision, retarders play an indispensable role in the seamless operation of hump yards.

Switch: Directing the Flow of Railway Cars

The heart of a hump yard lies in its network of classification tracks, where railway cars are sorted based on their destination or type. To ensure each car finds its designated track, a vital component comes into play: the switch.

Switches are movable tracks that guide cars onto the appropriate classification tracks. They act as railway traffic controllers, directing the flow of cars with precision. Switches can be actuated remotely or manually, depending on the yard’s size and complexity.

Remotely controlled switches are operated from a central control tower, allowing the yardmaster to oversee the entire humping process from a single location. Manual switches, on the other hand, are operated by yard workers using levers or buttons located near the tracks.

The accuracy and efficiency of switching are crucial for the smooth operation of a hump yard. Switches must be set precisely to prevent cars from derailing or entering the wrong tracks. Retarders, which control the speed of cars descending from the hump, work in conjunction with switches to ensure a safe and manageable entry into the classification tracks.

In modern hump yards, switches are often equipped with advanced monitoring systems. These systems provide real-time data on switch position, speed, and temperature, allowing yardmasters to monitor and adjust operations as needed. By optimizing switch performance, hump yards enhance overall efficiency and reduce delays.

Switches play a pivotal role in the intricate ballet of hump yard operations. They guide railway cars to their intended destinations, ensuring the seamless flow of freight throughout the rail network.

Caboose: The Last Line of Defense (Optional)

Traditionally, cabooses were the final car attached to freight trains, serving two primary purposes: additional braking power and accommodation for the train crew. Cabooses were equipped with handbrakes or air brakes that could be applied manually by the crew to assist in stopping the train. They also provided shelter and a workspace for the conductor and brakemen, who monitored the train’s progress and communicated with the locomotive engineer.

However, with the advent of modern locomotives equipped with advanced braking systems and improved communication technology, the need for cabooses has diminished. Today, they are primarily found in hump yards, where they serve as a safety measure.

In hump yards, cabooses are often attached to the end of trains that are being pushed over the hump for classification. Should any cars break loose and roll back down the hump, the caboose’s brakes can be applied to prevent a runaway situation. Additionally, cabooses provide a safe haven for crew members who need to inspect or repair cars while the train is in motion.

Despite their reduced use, cabooses remain an iconic symbol of the railroad industry. They represent the heritage and traditions of freight transportation and continue to play a role in ensuring the safety and efficiency of hump yard operations.

The Unsung Hero: The Yardmaster

In the heart of a bustling hump yard, where the thunderous roar of locomotives echoes through the air, there’s an unsung hero whose strategic decisions orchestrate the seamless flow of freight cars: the Yardmaster.

Like a conductor in a grand symphony, the Yardmaster oversees the intricate dance of humping, track switching, and train assembly. Perched atop a control tower, their piercing gaze commands a panoramic view of the yard’s vast expanse.

With a keen eye and a mind like a chessboard, they analyze the complex web of tracks and cars, determining the optimal routes for each. Their commands echo through the yard, guiding locomotives as they push cars up the towering hump, their momentum propelling them towards their destined tracks like cascading dominos.

Through a symphony of switches, the Yardmaster directs the cars down into their respective classification tracks, an intricate puzzle where each piece fits seamlessly into its place. Retarders, like gentle hands, control their descent, ensuring a safe and precise entry into the designated lanes.

The Yardmaster’s duties extend beyond mere logistics. They are the guardians of safety, ensuring a smooth and accident-free operation. With every decision they make, they safeguard the lives of their crew and the well-being of the precious cargo entrusted to them.

As the night falls and the yard hums with activity, the Yardmaster’s unwavering vigilance continues. They monitor the progress of humping operations, coordinating with locomotives and switching crews to ensure an uninterrupted flow. The clattering of wheels and the rhythmic creaking of cars become a lullaby to their weary souls.

Like a chess master, the Yardmaster anticipates the challenges that may arise, devising contingency plans to keep the yard running like a well-oiled machine. Their experience and dedication ensure that every car reaches its destination on time, a testament to their tireless efforts behind the scenes.

So, when you witness the rhythmic symphony of a hump yard, remember the unsung hero pulling the strings: the Yardmaster, the maestro of freight car movement. Without their unwavering guidance, the intricate machinery of the railroad industry would grind to a halt.