Protect your health and property with our comprehensive mold cleaning guide for OSB surfaces. Learn the dangers of mold, prepare with PPE and containment, and effectively remove mold growth using HEPA vacuuming, cleaning solutions, scrubbing, rinsing, drying, biocide treatment, and waste disposal. Ensure a thorough cleanup by addressing the specific considerations for OSB, including unique properties, potential damage, and sealing or replacement options.

The Perils of Mold: Why OSB Surfaces Demand Immediate Attention

Mold, a microscopic fungus, lurks in our homes and workplaces, posing a significant threat to both our health and our properties. When mold strikes OSB (oriented strand board), a common building material, it can compromise its structural integrity and unleash a host of health hazards.

OSB is particularly vulnerable to mold infestation due to its organic makeup and high moisture content. Mold thrives in damp environments and feeds on the cellulose fibers that make up OSB. As mold colonizes, it releases harmful spores into the air, which can trigger a range of respiratory problems, from mild allergies to severe infections. Prolonged exposure to mold can even lead to neurological and chronic health conditions.

The consequences of unchecked mold growth on OSB extend beyond gesundheit concerns. Mold can weaken the material, causing it to rot and lose its structural integrity. This can lead to costly repairs or even structural failures, jeopardizing the safety of your property.

Therefore, it is crucial to address mold growth on OSB surfaces promptly and effectively to protect both your health and your home.

Preparing for Mold Cleanup: Protect Yourself and Your Home

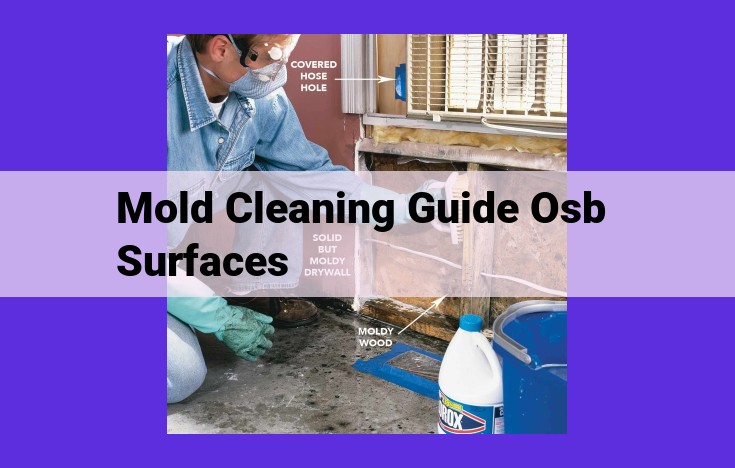

Before you tackle the daunting task of mold cleanup, it’s crucial to take steps to protect yourself and your family. Exposure to mold spores can trigger allergies, respiratory problems, and even more severe health issues. That’s why personal protective equipment (PPE) is an absolute must.

Don a mask rated at least N95 or higher to prevent inhaling harmful spores. Gloves, goggles, and protective clothing will shield your skin and eyes. This gear will act as your defense against potential mold exposure.

Proper waste disposal is another critical aspect of preparing for mold cleanup. Moldy materials, such as drywall, insulation, and carpeting, should be disposed of according to local regulations. Using labeled biohazard containers and coordinating with hazardous waste disposal services ensures safe and responsible handling.

By prioritizing PPE and waste disposal, you’re creating a safe and effective environment for mold cleanup, protecting both your health and your home.

Establishing a Containment Area: Confining Mold for Effective Cleanup

Mold cleanup necessitates the meticulous establishment of a containment area to prevent the spread of harmful spores throughout your home. This crucial step involves isolating the affected area, creating negative air pressure, and sealing off potential escape routes.

Isolating the Affected Area

- Identify the source: Determine the origin of the mold growth and mark its boundaries.

- Seal off entry points: Close off doorways, windows, and vents within the affected area to minimize mold dispersion.

- Cover openings: Use plastic sheeting or tarps to cover exposed surfaces, such as furniture, appliances, and countertops.

Creating Negative Air Pressure

- Install an exhaust fan: Position an exhaust fan in a window or doorway that leads outside the containment area. Vent the air directly outdoors using a duct or hose.

- Close other windows and doors: Ensure that there are no other openings that allow air to enter the containment area. This will create a negative air pressure, drawing air from outside into the affected area and exhausting it through the fan.

Preventing the Spread of Mold

- Use HEPA-filtered vacuum: Vacuum all surfaces within the containment area with a vacuum cleaner equipped with a High-Efficiency Particulate Air (HEPA) filter to capture mold spores.

- Wear personal protective equipment: Protect yourself with gloves, a respirator, and protective clothing when handling moldy materials.

- Minimize movement: Limit foot traffic within and out of the containment area to avoid disturbing settled mold spores.

By following these steps, you effectively confine the spread of mold growth, creating a controlled environment for safe and efficient cleanup.

HEPA Vacuum Cleaning: Removing Mold Spores with Precision

When tackling mold growth on OSB surfaces, using a HEPA vacuum is essential for removing mold spores effectively and minimizing contamination. These microscopic particles, often invisible to the naked eye, can trigger allergic reactions and respiratory problems.

Benefits of HEPA Vacuuming

A HEPA (High-Efficiency Particulate Air) vacuum is equipped with a specialized filter that captures 99.97% of particles down to 0.3 microns in size. This includes mold spores, pollen, dust mites, and other airborne irritants. By using a HEPA vacuum, you can significantly reduce the spread of mold spores and improve indoor air quality.

Proper Vacuuming Techniques

Before vacuuming, ensure the affected area is well-ventilated and wear appropriate personal protective equipment (PPE), such as a mask and gloves.

Start by vacuuming the entire area thoroughly, focusing on any visible mold growth. Use a soft-bristled attachment to avoid damaging the OSB.

Avoid vacuuming directly over the mold. Instead, use sweeping motions to gently loosen and remove spores.

Empty the vacuum cleaner frequently to prevent the accumulation of mold spores in the filter. Dispose of the vacuum cleaner bag or canister in a sealed hazardous waste container.

By following these proper vacuuming techniques, you can effectively remove mold spores and prevent their spread.

Selecting the Right Mold Cleaning Solution for OSB Surfaces

Navigating the Maze of Mold Cleaners

When it comes to mold cleanup, selecting the optimal cleaning solution is paramount. Different types of mold removers exist, each with varying effectiveness. However, for OSB (oriented strand board) surfaces, not all solutions are created equal.

Understanding OSB’s Unique Properties

OSB is a composite wood product made from strands of wood bonded together with resin. While it’s durable, OSB can be more susceptible to water damage than solid wood. Harsh chemicals or excessive moisture can damage the surface, compromising its integrity.

Choosing the Gentle Yet Effective Solution

To avoid damaging OSB, it’s essential to opt for a cleaning solution that’s both effective against mold and gentle on the surface. Here are a few recommended options:

- Enzyme-Based Cleaners: These solutions use enzymes to break down and digest mold. They’re relatively non-toxic and suitable for most OSB surfaces.

- Hydrogen Peroxide: This disinfectant is a powerful oxidizer that can kill mold spores. However, it can bleach the surface, so use it cautiously.

- Sodium Hypochlorite (Bleach): Bleach is a strong disinfectant, but it can damage the surface of OSB. Use it only in diluted form and on small areas.

Important Considerations

Before using any cleaning solution, test it on an inconspicuous area to ensure it doesn’t discolor or damage the OSB. Always follow the manufacturer’s instructions for dilution and application.

Additional Tips:

- Avoid using abrasive cleaners or steel wool, as they can scratch the surface.

- Ventilate the area well during and after cleaning to prevent mold spores from spreading.

- If the mold infestation is extensive or has penetrated deeply into the OSB, consider calling a professional mold remediation company.

Scrubbing and Rinsing: Removing Mold Growth

Mold colonization can spread rapidly by releasing microscopic spores into the air. To prevent further contamination and remove existing growth, thorough scrubbing and rinsing are crucial.

Selecting the Appropriate Cleaning Agents

The effectiveness of mold removal depends on the cleaning agents used. For OSB surfaces, non-bleach-based cleaners are recommended to avoid damaging the material. These cleaners contain enzymatic or peroxide-based ingredients that break down mold spores without compromising the integrity of OSB.

Scrubbing Technique

Apply the cleaning solution to the affected area using a stiff-bristled brush. Scrub vigorously in a circular motion to loosen and remove mold growth. Avoid using abrasive pads or steel wool, as these can scratch the surface. For stubborn mold, consider using a steam cleaner to penetrate deeper into the OSB.

Thorough Rinsing

After scrubbing, rinse the area thoroughly with clean water. Use a sponge or cloth to wipe away any remaining mold spores or cleaning residues. It’s important to rinse multiple times to ensure complete removal.

Drying to Prevent Regrowth

Once the area is clean, thorough drying is essential to prevent mold regrowth. Open windows and doors to promote air circulation. Alternatively, use fans or dehumidifiers to accelerate the drying process.

By following these steps, you can effectively remove mold growth from OSB surfaces and prevent its return.

Drying: Preventing Future Mold Growth

Once the cleaning process is complete, the key to preventing mold regrowth is thorough drying. Mold thrives in moist environments, so depriving it of moisture is crucial. For OSB surfaces, specific drying methods are recommended:

-

Air Drying: Open windows and doors to allow ventilation and promote air circulation. Use fans to increase airflow and speed up the drying process.

-

Dehumidifiers: Dehumidifiers remove moisture from the air, creating an environment less conducive to mold growth. For OSB surfaces, it’s recommended to use low-temperature dehumidifiers to avoid damaging the material.

-

Heat Drying: Heat can also be used to dry OSB surfaces. Use heaters or heat guns, but ensure they are set to a low temperature to prevent OSB damage. Avoid direct heat sources to prevent warping or scorching.

Thorough drying is vital for preventing future mold growth. By implementing these drying methods, you can effectively reduce moisture levels, creating an environment unfavorable to mold.

Biocide Treatment: Inhibiting Mold Regrowth

When dealing with mold growth on OSB surfaces, employing a biocide treatment is a crucial step to prevent its unwelcome return. Biocides, often referred to as fungicides, are chemical agents that effectively kill or inhibit the growth of mold and other microorganisms.

The selection of the most appropriate biocide for OSB surfaces depends on several factors, including the type of mold, the severity of the infestation, and the safety considerations. Common types of biocides used for mold remediation include:

- Borates: These non-toxic biocides are effective against a wide range of molds but can be corrosive to metals.

- Phenolics: These biocides provide long-lasting protection against mold growth.

- Quaternary ammonium compounds: These biocides are less corrosive than borates but may be less effective against certain types of mold.

When applying biocides on OSB surfaces, it’s paramount to prioritize safety. Ensure adequate ventilation and wear protective gear, such as gloves, goggles, and a respirator. Follow the manufacturer’s instructions meticulously to avoid potential hazards.

To effectively apply biocide treatments, follow these steps:

- Test a small area of the OSB surface to check for any adverse reactions before applying the biocide to the entire affected area.

- Apply the biocide using a sprayer, brush, or roller, ensuring even coverage.

- Allow the biocide to dwell for the recommended duration, usually several hours, to give it ample time to penetrate and eliminate the mold.

- Rinse the surface thoroughly with clean water to remove any residual biocide and prevent damage to the OSB.

After applying a biocide treatment, monitor the area regularly to ensure that the mold problem has been effectively addressed. If mold growth persists or reappears, it may be necessary to reapply the biocide or consider additional remediation measures.

Waste Disposal: Managing Contaminated Materials

When tackling mold cleanup, proper waste disposal is essential to prevent further contamination. All contaminated materials, including moldy surfaces, PPE, and HEPA vacuum bags, must be disposed of safely.

Hazardous waste services should be contacted for the removal of highly contaminated materials, such as large moldy sections of OSB. These companies have the proper equipment and training to handle and dispose of hazardous waste.

Alternatively, smaller contaminated items can be disposed of in double-lined biohazard bags. These bags should be clearly labeled with biohazard warnings and sealed securely before being placed in regular trash containers.

Keep in mind that local regulations regarding mold waste disposal may vary. It’s crucial to check with your local authorities for specific guidelines and requirements in your area.

Additional Considerations for OSB Surfaces

OSB (oriented strand board) is a type of engineered wood often used in construction due to its strength and affordability. However, OSB is highly susceptible to mold growth due to its porous nature. Therefore, when dealing with mold cleanup on OSB surfaces, it’s crucial to take extra precautions to avoid damaging the material.

When cleaning mold off OSB, always test an inconspicuous area first to ensure the cleaning solution doesn’t cause discoloration or damage. Use gentle scrubbing techniques and avoid using harsh chemicals or abrasive materials. Moreover, _allow the surface to dry completely_ after cleaning to prevent further mold growth.

In severe cases, you may need to replace the affected OSB. If possible, seal the remaining OSB surfaces with a mold-resistant sealant to prevent future mold growth. When replacing OSB, be sure to use mold-resistant sheathing and install it properly to prevent future moisture problems.

_Remember, mold cleanup on OSB Surfaces requires special care. By following these additional considerations, you can effectively remove mold and restore your OSB surfaces without causing further damage.