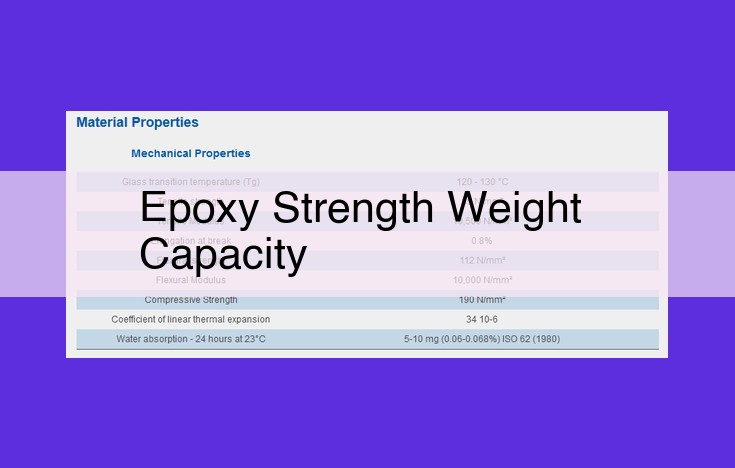

Epoxy resin exhibits exceptional strength characteristics, including tensile, compressive, flexural, and shear strength. Its stiffness and elasticity are quantified by Young’s modulus and Poisson’s ratio. The material’s low density contributes to its impressive specific strength and specific modulus, making it an ideal choice for applications where strength-to-weight ratio matters.

Tensile Strength:

- Definition: Explain the ability of epoxy resin to deform without breaking.

- Key Concepts: Discuss ductility, yield strength, and ultimate tensile strength.

Tensile Strength: The Unsung Hero of Epoxy Resins

In the world of materials, tensile strength reigns supreme as the defining characteristic of strength and resilience. It’s the ability of a material to withstand deformation and stress without snapping like a twig. When it comes to epoxy resins, this property takes center stage.

Defining Tensile Strength

Tensile strength measures how much force it takes to pull a material apart. It’s like a tug-of-war between the material and a relentless force. As the force increases, the material will stretch and deform. If it can handle the strain and doesn’t break, then it has high tensile strength.

Key Concepts to Remember

- Ductility: How much a material can stretch before it breaks.

- Yield Strength: The minimum force required to permanently deform the material.

- Ultimate Tensile Strength: The maximum force a material can withstand before failure.

So, what makes epoxy resins exceptional when it comes to tensile strength? They exhibit remarkable ductility, meaning they can stretch significantly before breaking. This makes them perfect for applications where flexibility and resistance to tearing are crucial. For example, they’re used in flexible coatings, adhesives, and even in some sporting goods.

Moreover, epoxy resins boast high yield and ultimate tensile strength, indicating their ability to withstand high forces and deformation without catastrophic failure. This makes them a go-to choice for load-bearing structures, composites, and coatings that demand structural integrity.

In essence, the tensile strength of epoxy resins is the backbone of their strength and resilience. It’s a testament to their ability to withstand the rigors of everyday use, making them a versatile and reliable choice for a wide range of applications.

Compressive Strength: The Epoxy Resin’s Unwavering Resistance to Crushing

In the realm of materials, compressive strength reigns as a crucial measure of a substance’s ability to withstand the forces that threaten to crush it. Epoxy resin, known for its versatility and exceptional properties, exhibits remarkable compressive strength that makes it an ideal choice for a wide range of applications.

Imagine a mighty warrior standing firm against an onslaught of forces relentlessly pushing down on him. Just as the warrior steadfastly resists, epoxy resin stands tall against the unrelenting pressure of compressive forces. Its innate ability to противостоять being crushed grants it immense practicality in applications ranging from aircraft components to high-performance structures.

The compressive strength of epoxy resin is characterized by two key concepts: crushing strength and yield strength in compression.

Crushing Strength: The Ultimate Measure of Strength

Crushing strength represents the maximum stress that epoxy resin can endure before it crumbles under pressure. This value serves as a critical indicator of the material’s overall ability to withstand crushing loads. In other words, it measures the ultimate resistance of epoxy resin to being squeezed or crushed.

Yield Strength in Compression: The Point of No Return

Yield strength in compression, on the other hand, marks the point at which permanent deformation begins to occur in the epoxy resin. Beyond this critical threshold, the material exhibits irreversible changes in its shape or structure. This value helps engineers understand the limitations of epoxy resin’s compressive strength and prevent its use in applications where it may be subjected to excessive crushing forces that could lead to failure.

By understanding the compressive strength of epoxy resin, engineers and designers can harness its exceptional ability to resist crushing forces. This knowledge empowers them to create structures and products that can withstand the rigors of demanding environments, ensuring their durability and reliability.

Flexural Strength: The Strength of Epoxy Resin Under Bending

When it comes to epoxy resins, the ability to withstand bending forces is crucial. This flexural strength determines the material’s resistance to deformation and breakage when subjected to bending loads. Understanding this property is essential for applications involving epoxy resins in structural components or load-bearing situations.

The modulus of rupture is a key concept in flexural strength, representing the maximum stress that epoxy resin can withstand before fracturing. It measures the material’s ability to resist bending without breaking. Higher modulus of rupture values indicate greater flexural strength.

Bend strength is another important metric for flexural properties. It measures the force required to bend an epoxy resin sample by a specific angle. Epoxy resins with higher bend strength can withstand greater bending loads without deforming or snapping.

In applications such as composite materials, high flexural strength is essential for resisting bending forces encountered during use. Understanding these properties ensures that epoxy resins are chosen appropriately for various applications, ensuring structural integrity and durability.

Shear Strength of Epoxy Resin: Exploring Its Resistance to Lateral Forces

When it comes to the structural integrity of epoxy resin, shear strength plays a crucial role. This property measures the material’s ability to withstand forces applied parallel to its surface. In layman’s terms, it indicates how well epoxy resin resists twisting, sliding, or shearing.

Key Concepts:

- Ultimate Shear Strength: This is the maximum amount of shear stress that epoxy resin can handle before it ruptures. If the applied force exceeds this threshold, the material fails.

- Yield Shear Strength: This is the point at which epoxy resin undergoes permanent deformation under shear stress. Beyond this point, the material’s shape changes irrevocably.

Epoxy resin’s shear strength is influenced by factors such as its chemical composition, curing time, and temperature. By carefully controlling these parameters, manufacturers can tailor epoxy resins to meet specific application requirements. High-shear-strength resins are ideal for applications where components are subjected to significant lateral forces, such as in bonding structural elements or creating composite materials.

Understanding shear strength is paramount for engineers, designers, and hobbyists working with epoxy resin. By considering the forces acting on a given structure, they can select the appropriate resin and application techniques to ensure optimal performance and durability.

Young’s Modulus: Quantifying the Stiffness and Elasticity of Epoxy Resin

When it comes to assessing the mechanical properties of materials, Young’s Modulus plays a crucial role. It provides insights into the material’s resistance to deformation and its ability to return to its original shape, making it a vital consideration for various engineering applications. In this article, we delve into the concept of Young’s Modulus, specifically focusing on its significance in the context of epoxy resin.

Definition and Key Concepts

Young’s Modulus, denoted by the symbol E, is a measure of a material’s stiffness. It represents the ratio of stress (force per unit area) to strain (deformation per unit length) within the elastic region of the material. In simpler terms, it quantifies the resistance of a material to deformation under an applied force.

Stress and Strain Relationship

To understand Young’s Modulus, it’s essential to grasp the relationship between stress and strain. Stress refers to the force applied to a material per unit area, while strain represents the deformation or change in length of the material as a result of the applied force. In the context of epoxy resin, a higher Young’s Modulus indicates that the material is stiffer and more resistant to deformation.

Significance in Material Behavior

The value of Young’s Modulus provides valuable insights into the behavior of epoxy resin under load. A higher Young’s Modulus implies that the material is more difficult to stretch or compress, requiring a greater force to induce the same amount of deformation. This characteristic is crucial for applications where rigidity and dimensional stability are essential.

Application in Engineering Design

In engineering design, understanding the Young’s Modulus of epoxy resin is vital for selecting materials that meet specific performance requirements. It helps engineers predict the material’s response to external forces and ensures the structural integrity of components and systems. For instance, in aerospace applications, materials with a high Young’s Modulus are often used to withstand the extreme forces encountered during flight.

Young’s Modulus is a fundamental mechanical property that provides valuable insights into the stiffness and elasticity of epoxy resin. By understanding this property, engineers can make informed decisions when selecting materials for various applications, ensuring optimal performance and durability in demanding environments. Whether it’s for high-strength adhesives or rigid structural components, the knowledge of Young’s Modulus empowers engineers to harness the unique properties of epoxy resin in their designs.

Poisson’s Ratio: Understanding Epoxy Resin’s Deformation Behavior

Elasticity is a fundamental property that describes a material’s ability to return to its original shape after being deformed. Epoxy resin, known for its strength and durability, also exhibits an intriguing deformation behavior, known as Poisson’s ratio.

Definition

Poisson’s ratio measures the tendency of a material to deform in one direction when force is applied in another. It represents the ratio of lateral strain (change in width) to axial strain (change in length) when a force is applied.

Role of Elasticity

Materials with high elasticity, like epoxy resin, exhibit a noticeable change in shape when a force is applied. The ratio between the lateral and axial strain is known as Poisson’s ratio. A positive ratio indicates that the material becomes narrower when stretched and wider when compressed.

Understanding Poisson’s Ratio

For most materials, Poisson’s ratio typically ranges from -1 to 0.5. A Poisson’s ratio of -1 would indicate that the material expands in all directions when stretched, while a ratio of 0.5 would indicate that it contracts in one direction while expanding in the other.

Epoxy resin typically has a Poisson’s ratio close to 0, indicating that it exhibits minimal lateral deformation when subjected to axial forces. This means that when stretched, epoxy resin tends to maintain its width, making it a suitable choice for applications where dimensional stability is crucial.

Applications

Understanding Poisson’s ratio is essential for optimizing epoxy resin applications. In structural engineering, materials with a low Poisson’s ratio, like epoxy resin, are often used to minimize deformation under load. In microelectronics, epoxy resin is employed as a protective coating due to its ability to withstand expansion and contraction without compromising its integrity.

Poisson’s ratio is a valuable parameter that provides insight into the deformation behavior of epoxy resin. By understanding this property, engineers and designers can tailor their material selection and optimize epoxy resin use for a wide range of applications, ensuring structural stability and performance.

Understanding the Mass of Epoxy Resin: Exploring Density

In the realm of materials, density reigns supreme as a crucial property that governs an array of physical characteristics. For epoxy resin, this attribute plays a pivotal role in determining its weight, strength, and capacity. Density is defined as the mass per unit volume of a substance. In simpler terms, it measures how much mass is packed into a given volume of material.

The density of epoxy resin typically ranges between 1.15 and 1.25 grams per cubic centimeter (g/cm³). This value indicates that for every cubic centimeter of epoxy resin, there is approximately 1.15 to 1.25 grams of mass. The density of epoxy resin is influenced by several factors, including the type of resin, additives, and curing conditions.

Understanding the impact of density on epoxy resin is crucial for various applications. For instance, in weight-sensitive scenarios, such as aerospace and automotive industries, a lower density epoxy resin is preferred to reduce overall component weight. On the other hand, in structural applications where strength is paramount, a higher density epoxy resin is often utilized to withstand heavier loads.

Moreover, density influences other properties of epoxy resin, such as its strength-to-weight ratio and stiffness-to-weight ratio. These ratios, known as specific strength and specific modulus, respectively, are crucial for applications where both strength and weight are critical considerations.

By comprehending the density of epoxy resin, engineers and designers can make informed choices when selecting this versatile material for their specific applications. Understanding its weight, strength, and capacity ensures optimal performance and longevity in a wide range of industries.

Epoxy Resin: Unraveling Its Extraordinary Strength and Lightweight Properties

Imagine a material that combines the robustness of steel with the lightness of a feather. Epoxy resin is that remarkable substance, offering an unparalleled blend of strength and weight reduction.

Specific Strength: The Essence of Strength-to-Weight Ratio

Specific strength, measured as strength per unit weight, is a crucial parameter that governs a material’s suitability for various applications. Epoxy resin excels in this aspect, boasting a high specific strength that makes it ideal for weight-sensitive designs.

This unique property stems from its exceptional strength despite its low density. In other words, for a given weight, epoxy resin provides far greater strength than many traditional materials.

Applications that Thrive on Specific Strength

The lightweight nature of epoxy resin, coupled with its impressive strength, opens up a multitude of applications where weight optimization is paramount.

-

Aerospace Industry: Aircraft and spacecraft components demand materials that are both strong and lightweight to maximize performance and fuel efficiency. Epoxy resin fits this bill perfectly.

-

Automotive Sector: In the automotive industry, weight reduction is crucial for improved fuel consumption and enhanced handling. Epoxy resin’s high specific strength makes it an ideal choice for body panels, bumpers, and other weight-critical components.

-

Medical Devices: Medical implants and prosthetics must withstand stress while minimizing weight for patient comfort. Epoxy resin’s specific strength ensures durability and wear resistance in these demanding applications.

Unleashing the Potential of Specific Strength

The versatility of epoxy resin extends beyond its inherent strength-to-weight ratio. By tailoring the resin’s composition and reinforcement, engineers can further enhance its specific strength. This customization allows for the development of materials that meet the precise performance requirements of specific applications.

Epoxy resin’s exceptional specific strength makes it an indispensable material in countless industries. From the weight-critical aerospace sector to the demanding medical field, epoxy resin empowers engineers to design and construct structures that are both strong and lightweight. As technology advances, we can expect even more innovative applications of this remarkable material.

Epoxy Resin: Unraveling Its Exceptional Strength, Weight, and Capacity

Introduction:

Epoxy resin, a remarkable material with unparalleled properties, has revolutionized various industries. Its exceptional strength, lightweight nature, and versatile applications make it an ideal choice for countless projects. In this blog post, we’ll delve into the intricacies of epoxy resin’s strength, weight, and capacity, empowering you with the knowledge to make informed decisions in your next project.

Specific Modulus: The Strength-to-Weight Champion

Specific modulus is a crucial parameter that measures the stiffness-to-weight ratio of epoxy resin. It indicates the material’s ability to resist bending and deformation relative to its weight. The higher the specific modulus, the stiffer and lighter the epoxy resin, making it an ideal choice for applications where weight saving is paramount.

This property is particularly relevant in industries such as aerospace, automotive, and sporting goods, where weight reduction is essential for enhancing performance and efficiency. By utilizing epoxy resins with high specific moduli, engineers can create lightweight components that can withstand demanding loads and harsh conditions.

Benefits of High Specific Modulus

The advantages of using epoxy resins with high specific moduli are numerous:

- Increased durability: Stiffer materials resist deformation, prolonging their lifespan and ensuring reliable performance.

- Enhanced efficiency: Lightweight components reduce energy consumption in vehicles, aircraft, and other applications where weight plays a significant role.

- Improved aesthetics: Sleeker and more streamlined designs can be achieved by using lighter materials, enhancing the overall appeal of products.

Applications of Epoxy Resins with High Specific Moduli

The versatility of epoxy resins extends to a wide range of applications where their exceptional strength-to-weight ratio is crucial:

- Composite materials: Epoxy resins are used as matrices in composite materials, combining strength and lightness for applications in aerospace, marine, and construction.

- Structural components: Epoxy resins are employed in the fabrication of lightweight structural components for vehicles, bridges, and buildings.

- Sporting equipment: Golf clubs, tennis rackets, and bicycles utilize epoxy resins for their high specific modulus, enhancing performance and durability.

Epoxy resin is a versatile and high-performing material that offers an impressive combination of strength, weight, and capacity. Its specific modulus is a key parameter that engineers and designers consider to optimize performance in weight-sensitive applications. As technology advances, the development of epoxy resins with even higher specific moduli opens up new possibilities for lightweight and durable designs, revolutionizing industries across the board.

Glass Transition Temperature:

- Definition: Explain the glassy state of epoxy resin below its glass transition temperature.

- Key Concepts: Discuss the impact of temperature on the material’s properties, including rigidity and brittleness.

Understanding Epoxy Resin’s Strength, Weight, and Capacity: A Comprehensive Guide

Epoxy resin, known for its versatility and durability, exhibits a wide range of mechanical properties that make it suitable for various applications. Its tensile strength measures its ability to resist deformation without breaking, indicating its resilience under stretching forces. Key concepts to understand include ductility, yield strength, and ultimate tensile strength.

Moving on to compressive strength, we delve into the resin’s resistance to being crushed. This property is defined by crushing strength and yield strength in compression, indicating how well the material withstands force applied directly to its surface.

Next, we explore flexural strength, which gauges the resin’s ability to resist bending. This is expressed in terms of modulus of rupture and bend strength, highlighting the material’s capacity to endure applied forces that cause it to bend.

Shear strength is another crucial aspect, referring to the resin’s resistance to forces applied parallel to its surface. This property is measured by ultimate shear strength and yield shear strength, providing insights into its behavior under shearing forces.

Understanding Young’s Modulus is key to comprehending the resin’s stiffness and elasticity. This property quantifies the relationship between stress and strain, indicating the material’s resistance to deformation and its ability to return to its original shape.

Poisson’s Ratio delves into the resin’s tendency to deform in one direction when force is applied in another. This concept helps understand the material’s elasticity and provides valuable information for design applications.

Density is a fundamental property that measures the mass per unit volume of the resin. It plays a crucial role in determining the weight and other physical characteristics of the material.

Specific Strength and Specific Modulus are key considerations for applications where weight optimization is critical. These properties represent the strength-to-weight and stiffness-to-weight ratios of the resin, respectively, highlighting its efficiency in these aspects.

Finally, we delve into the Glass Transition Temperature, a vital property that indicates the resin’s transition from a glassy state to a rubbery state upon heating. Understanding this temperature and its impact on rigidity and brittleness is essential for proper material selection and design optimization.

In conclusion, this comprehensive guide has shed light on the diverse mechanical properties of epoxy resin, providing valuable insights for informed decision-making and effective use of this versatile material across a wide range of applications.