Pinion bearing preload check and adjustment ensure proper mesh between pinion and ring gears, minimizing vibration, noise, and enhancing bearing life. Using specific tools, the procedure involves setting up a dial indicator to measure bearing play, applying torque to the pinion nut, and adjusting the preload within specified tolerances. Understanding the principles of taper roller bearings, vibration control, noise reduction, and bearing life is essential. Proper preload reduces stress on bearings, optimizes lubrication, and enhances overall performance of the differential.

Understanding the Vital Role of Pinion Bearing Preload

In the intricate world of drivetrain systems, pinion bearings play a critical role in ensuring smooth operation and longevity. Pinion bearing preload is a crucial adjustment that optimizes bearing performance by minimizing vibration, reducing noise, and extending bearing life. Here’s why it matters:

-

Minimizing Vibration: Excessive vibration can be a nuisance and cause stress on other components. Preload helps eliminate play and ensures the pinion gear meshes smoothly with the ring gear, reducing chatter and vibrations.

-

Reducing Noise: Noise is another common concern. By eliminating play, preload reduces the impact forces on the gear teeth, which in turn minimizes noise levels.

-

Enhancing Bearing Life: Proper preload ensures the bearings are adequately loaded, preventing excessive stress and premature failure. This helps extend the lifespan of the bearings and reduces the need for costly replacements.

Essential Tools for Pinion Bearing Preload Adjustment

Pinion bearing preload is a critical factor in enhancing drivetrain performance and durability. To ensure proper adjustment, you’ll need an array of essential tools. Let’s delve into the toolkit necessary for this meticulous task.

-

Dial Indicator: This precision instrument accurately measures bearing play and ensures optimal preload.

-

Torque Wrench: A reliable torque wrench is indispensable for tightening the pinion nut to specified torque values.

-

Hydraulic Press: A hydraulic press is often required to install and remove pinion bearings.

-

Measuring Gage: A measuring gage accurately determines bearing clearances and ensures proper preload.

-

Feeler Gage: A feeler gage helps measure bearing play by inserting it between the pinion gear and the bearing race.

-

Lock Plate: The lock plate prevents the pinion nut from loosening and maintains proper preload over time.

-

Spanner Wrench: A spanner wrench is specifically designed to remove and install the pinion nut.

-

Hammer and Punch: A hammer and punch are essential for driving out the old lock plate and installing a new one.

-

Safety Glasses and Gloves: Safety should always be paramount. Wear appropriate safety gear to protect your eyes and hands.

These tools empower you to perform the delicate task of adjusting pinion bearing preload with precision and confidence. By equipping yourself with these essential items, you can ensure a smooth-running and long-lasting drivetrain.

Prerequisites for Pinion Bearing Preload Adjustment: Setting the Stage for Precision

Before embarking on the precise task of adjusting pinion bearing preload, several crucial preparatory steps must be meticulously completed. These steps lay the foundation for an accurate and successful preload adjustment procedure.

Differential Assembly: A Solid Foundation

Prior to adjusting pinion bearing preload, the differential assembly itself must be fully assembled. This includes the installation of all differential gears, bearings, and components within the differential housing. A correctly assembled differential ensures proper gear engagement and rotation, which is essential for accurate preload determination.

Pinion Gear Installation: The Heart of the Matter

Once the differential assembly is complete, the pinion gear must be installed. This involves carefully positioning the pinion gear on the pinion shaft and securing it using the appropriate bolts or nuts. The pinion gear’s proper installation ensures that it aligns precisely with the differential gears, creating the optimal conditions for preload adjustment.

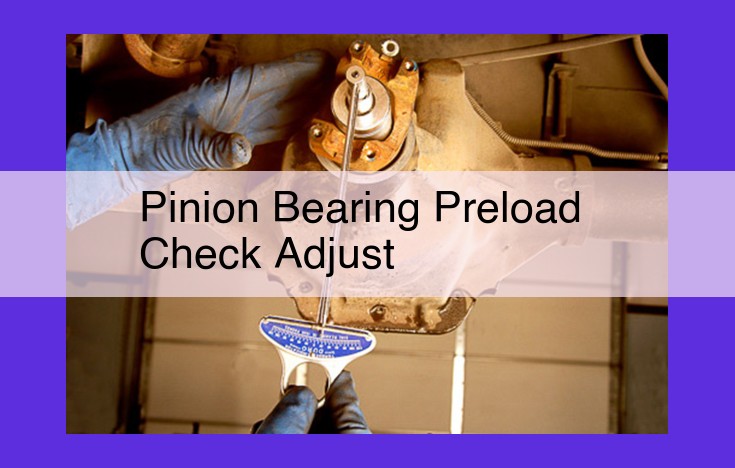

Step-by-Step Preload Check and Adjustment Process

Dial Indicator Setup

- Mount a dial indicator onto the differential housing.

- Set the dial indicator tip on the pinion gear’s face.

- Ensure that the dial indicator is parallel to the pinion shaft.

Torque Application

- Tighten the pinion nut to the specified torque using a torque wrench.

- Hold the torque wrench steady while tightening.

Bearing Play Check

- Loosen the pinion nut by 1/4 turn.

- Gently push and pull on the pinion gear to measure bearing play.

- The play should be within the specified range.

- If the play is excessive, tighten the pinion nut slightly. If the play is too small, loosen the pinion nut slightly.

Preload Adjustment

- Repeat steps 1 and 2 above.

- Set the dial indicator to zero.

- Tighten the pinion nut while observing the dial indicator.

- Stop tightening when the dial indicator reads the specified preload value.

- Lock the pinion nut in place.

Note: Preload adjustment may vary depending on differential type and specifications. Always consult the manufacturer’s instructions for specific guidelines.

Related Concepts

To delve into the complexities of pinion bearing preload, it’s essential to understand a few fundamental concepts:

Taper Roller Bearing:

At the heart of the pinion bearing is the taper roller bearing, a type of anti-friction bearing designed to handle heavy radial and axial loads. Its unique tapered design allows for proper contact stress distribution, minimizing wear and prolonging bearing life.

Vibration Control:

Vibration in automotive transmissions can create unpleasant noise and compromise performance. Pinion bearing preload plays a crucial role in controlling vibration by maintaining a specific amount of tension on the bearing components. This preload prevents excessive movement and reduces vibration transmission to the driveline.

Noise Reduction:

Noise generation within a transmission can be a major annoyance. Proper preload minimizes noise by reducing the play between bearing components. When bearings have excessive play, they can rattle and create noise. By maintaining the correct preload, noise levels are significantly reduced.

Bearing Life:

Preload also significantly impacts bearing life. Too little preload can cause excessive movement and wear, while too much preload can lead to premature bearing failure. Finding the optimal preload is crucial for ensuring maximum bearing life and minimizing the need for costly replacements.