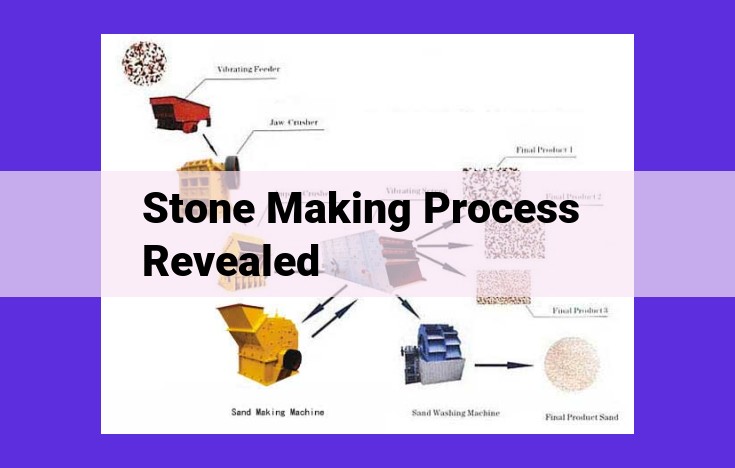

- Quarrying: Extracting blocks from quarries.

- Cutting: Shaping stones using saws and grinders.

- Finishing: Polishing surfaces using honing and polishing wheels.

- Fabrication: Creating customized products using CNC machines.

- Installation: Setting stones in place with mortar and anchors.

- Specialized Techniques and Equipment: Excavators, drills, and advanced tools used in each stage.

- Conclusion: Understanding the stone making process is crucial for appreciating its significance.

Quarrying: The Source of Stone

- Definition: Explain the process of extracting stone blocks from quarries.

- Related Concepts: Cover terms like excavation, mining, and drilling.

Quarrying: The Source of Stone

In the realm of construction and design, stone has played an integral role for centuries, embodying both beauty and durability. Before this remarkable material finds its way into our homes and structures, it undergoes a complex journey that begins deep within the earth’s crust.

The Extraction Process

Quarrying is the method by which stone blocks are extracted from the depths of quarries. This process involves excavating, or digging into the earth, using heavy machinery such as excavators and drills. Mining, a technique often employed in the extraction of precious stones, can also be utilized for certain types of stone. Skilled workers carefully remove the overburden, or layers of soil and rock covering the stone deposit, revealing the valuable resource beneath.

Related Concepts

Understanding the terminology associated with quarrying is crucial. Drilling refers to the process of creating holes in the stone, either for blasting or to place anchors for later extraction. Excavation encompasses the removal of materials to expose the stone deposit, while blasting involves using explosives to break down the stone into manageable blocks.

Environmental Considerations

Quarrying can have significant environmental implications. Responsible quarry operators implement measures to minimize these impacts, such as controlling dust and noise, reclaiming land after operations conclude, and protecting local ecosystems. Sustainable quarrying practices ensure that the extraction of stone does not compromise the environment for future generations.

Cutting: Transforming Stone into Architectural Masterpieces

In the realm of stone making, cutting plays a pivotal role in shaping raw blocks into refined masterpieces. This intricate process involves a delicate balance of precision, artistry, and a mastery of specialized techniques.

Techniques for Taming Stone

At the heart of stone cutting lies a symphony of tools, each designed to mold and sculpt the unyielding material. Saws bite into stone with diamond-tipped blades, creating crisp and precise lines. Grinders smoothen surfaces and refine edges, while sanders add a touch of finesse, creating a silky-smooth finish.

Shaping and Trimming: Defining the Form

The process of cutting begins with shaping, where rough stone blocks are transformed into desired sizes and dimensions. Precision saws contour the stone, creating clean cuts and angles that adhere to architectural plans. Trimming follows, where imperfections are removed and delicate details are carved into the stone’s surface.

Carving: Imparting Artistic Nuances

When mere cutting is not enough, carving elevates the stone to an artistic plane. Skilled craftsmen wield chisels and hammers to create intricate designs, reliefs, and sculptures. Each stroke imparts a unique character to the stone, breathing life into architectural masterpieces that transcend mere functionality.

The cutting of stone is more than just a technical process; it is an art form that combines precision with artistry. By mastering the techniques of cutting, shaping, trimming, and carving, stone masons transform raw blocks into architectural wonders that adorn buildings and monuments for centuries to come.

Finishing: Polishing for a Smooth Surface

The stone’s journey towards becoming a refined masterpiece doesn’t end at cutting and shaping. The next crucial step, finishing, transforms the raw stone into a smooth and lustrous surface.

Various techniques are employed to achieve this polished allure. Honing is a process that involves smoothing the stone using abrasives, resulting in a matte finish. For a more refined shine, polishing employs finer abrasives to create a reflective surface. Tumbling is a gentler method that uses rotating barrels filled with abrasive materials to create a softer, more natural texture.

Honing: Unveiling the Stone’s Character

Honing preserves the stone’s natural color and texture, enhancing its character. It’s commonly used on limestone, travertine, and sandstone, as it maintains their inherent charm while creating a soft, velvety finish. Honed surfaces are also less susceptible to scratches and stains, making them ideal for high-traffic areas.

Polishing: A Mirror-Like Perfection

Polishing transforms the stone into a mirror-like surface, revealing its vibrant hues and intricate patterns. Granite, marble, and quartzite are often polished due to their ability to withstand the intense process. Polished surfaces are ideal for countertops, kitchen backsplashes, and decorative elements that demand a sophisticated and eye-catching look.

Tumbling: Nature’s Gentle Touch

Tumbling mimics the natural weathering process, resulting in a surface that resembles the stones found in riverbeds or seashores. It’s a popular choice for pebbles and smaller stones used in landscaping, pathways, and decorative features. Tumbled surfaces have a rustic and organic appeal that adds depth and character to outdoor spaces.

Finishing is a crucial step in the stone making process, transforming raw stone into polished masterpieces that grace our homes, workplaces, and public spaces. By understanding the different techniques available, we appreciate the artistry and craftsmanship that goes into creating these beautiful and durable surfaces.

Fabrication: Crafting Bespoke Stone Creations

In the realm of stone craftsmanship, fabrication stands as the art of transforming raw stone blocks into exquisite custom products. This intricate process involves a symphony of prefabrication, meticulous manufacturing, and thoughtful design considerations.

Prefabrication: Setting the Stage

Prior to fabrication, stone slabs undergo meticulous prefabrication. Using advanced machinery, these slabs are cut and shaped into precise dimensions, ensuring they seamlessly fit their intended applications. The precision of this stage lays the foundation for the artistry that follows.

Manufacturing: Sculpturing Stone with Precision

The fabrication process kicks off with cutting and shaping the stone. Skilled craftsmen wield saws, grinders, and sanders, meticulously sculpting the stone into the desired form. This stage demands an astute eye for detail and an unwavering dedication to precision.

Design Considerations: A Canvas for Creativity

Fabrication transcends mere cutting and shaping, embracing the world of design. Architects and interior designers collaborate with stone fabricators, infusing their visions into every aspect of the process. From elaborate countertops to intricate tiles, fabrication empowers the creation of bespoke designs that reflect unique styles and aesthetic sensibilities.

The Culmination: A Symphony of Stone and Craftsmanship

Through the harmonious interplay of prefabrication, manufacturing, and design, fabrication culminates in the birth of breathtaking stone creations. Countertops, tiles, and other custom products emerge as testaments to the skill and artistry of stone artisans. These creations not only enhance the functionality of spaces but also elevate their aesthetic appeal, leaving an enduring legacy of beauty and craftsmanship.

Installation: Setting Stone in Place

The final stage of the stone-making process is installation. This involves carefully setting the stone in its intended location, ensuring its stability, durability, and aesthetic appeal.

Setting the Stone

The first step is to prepare the foundation where the stone will be installed. This may involve creating a solid and level surface, such as a concrete pad or a bed of mortar. The stone is then placed onto the prepared surface and adjusted to ensure its proper alignment and position.

Grouting

Grouting is a crucial step that helps to secure the stone in place and prevent shifting or movement. A grout mixture, typically made from cement or epoxy, is poured into the spaces between the stone pieces. The grout is spread evenly and allowed to cure, filling the gaps and creating a strong bond between the stones.

Anchoring

For larger or heavier stones, additional support may be necessary in the form of anchors. Anchors are metal devices, such as bolts or rods, that are inserted into the stone and the underlying foundation. These anchors help to prevent the stone from moving or becoming dislodged, especially in areas where there is significant weight or potential for movement.

Ensuring a Secure and Aesthetic Installation

Proper installation requires attention to detail to ensure not only the structural integrity of the stone but also its aesthetic appeal. The joints between the stone pieces should be neat and uniform, and the stone should be set level and even. Skilled craftsmen use precision techniques to achieve a seamless and visually pleasing finish.

Proper installation is essential for the longevity and beauty of stone structures. By understanding the techniques involved in setting, grouting, and anchoring, you can appreciate the craftsmanship and expertise that go into creating these timeless architectural elements.

Specialized Techniques and Equipment in Stone Making

Quarrying

In the heart of the quarry, excavators with mighty arms and drills as sharp as a dagger extract massive stone blocks from the earth’s embrace. These machines, guided by skilled hands, penetrate the rock’s depths, preparing it for its transformation.

Cutting

Once the stone is freed from its natural habitat, it enters the realm of cutting. Saws, with teeth as precise as a surgeon’s scalpel, carve intricate shapes into the raw material. Grinders and sanders dance across the stone’s surface, refining the edges and smoothing the imperfections, like a sculptor chiseling away at a masterpiece.

Finishing

To achieve a surface as smooth as glass, the stone undergoes a delicate process called finishing. Honing wheels gently caress the material, removing any remaining imperfections. Polishing wheels, like tiny hands, bring forth a brilliant luster, creating a surface that shimmers like a mirror.

Fabrication

The skilled hands of craftsmen and the precision of CNC machines collaborate in the fabrication stage. From countertops to tiles, each piece is meticulously designed and crafted, transforming raw stone into functional and aesthetically pleasing products. Advanced tools, like laser cutters and water jets, add intricate details, opening up endless possibilities for creativity.

Installation

The final step in the stone making process is installation. With precision and care, skilled professionals secure the stone in its intended location. Mortar, a bonding agent as strong as granite, holds the stone firmly in place. Grout, a filler as fine as sand, seals the joints, creating a seamless and durable surface. Anchors provide additional support, ensuring the stone withstands the test of time.

By combining traditional techniques with innovative equipment, the stone making process seamlessly transforms nature’s gift into architectural marvels and functional works of art. Each stage, from quarrying to installation, is a testament to human ingenuity, precision, and a deep appreciation for the beauty of stone.