A comprehensive guide to understanding Torx bits: it covers the various measurements, sizes, lengths, drive types, materials, head styles, and magnetic features. This guide explains the significance of Torx bit size designation (T1-T100) and its correlation with fastener dimensions. It also highlights the practical implications of bit length and the compatibility of drive types. Different materials used in Torx bits and their impact on durability are discussed. Additionally, the guide delves into the specific applications and benefits of magnetic Torx bits.

In the world of fasteners, Torx bits stand out with their unique six-lobed star-shaped design. Unlike traditional Phillips or flathead bits, Torx bits provide superior grip and torque transmission, making them indispensable in various industries and applications. For those unfamiliar with this specialized hardware, let’s delve into the world of Torx bits and explore their key characteristics.

At its core, a Torx bit is a driver bit featuring six raised lobes arranged in a star pattern. This design allows for a secure fit with Torx screws, which feature a matching six-lobe recess. The result is a snug engagement that resists cam-out (slipping) and ensures optimal torque transfer.

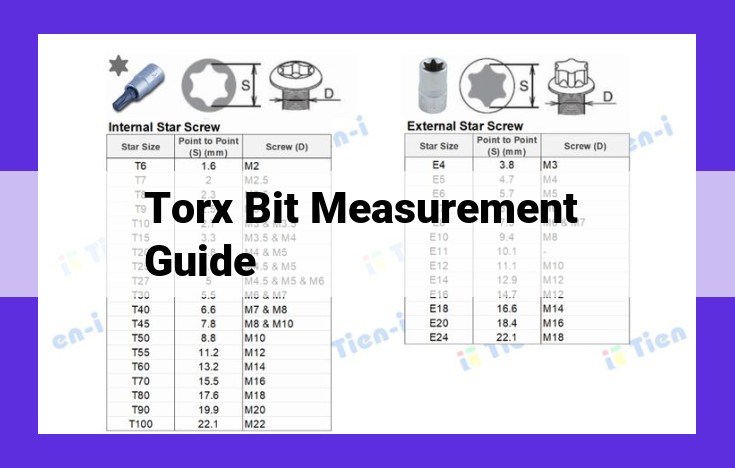

Understanding Torx bit measurements is crucial for selecting the right size for your application. Measurements are designated by a simple letter-number combination, typically “T” followed by a number indicating the bit’s size. Larger numbers indicate larger bits and, consequently, larger Torx screws. The correct size ensures a proper fit and prevents damage to the screw or fastener.

Beyond size, Torx bits also vary in length. The length is measured from the tip of the bit to the base of the drive end. Longer bits are suitable for deep-seated screws or recessed areas. Shorter bits are ideal for shallow screws or applications with limited clearance.

Torx Bit Sizes: A Guide to Understanding the Numbers

When working with Torx fasteners, it’s crucial to understand the intricate world of bit sizes. These seemingly complex designations hold the key to choosing the right bit for the job and ensuring a secure and efficient connection.

The Torx bit size designation system is a straightforward numerical ladder, ranging from T1 to T100. Each number corresponds to a specific size, with a higher number indicating a larger bit. However, the relationship between size and fastener dimensions isn’t always intuitive.

To simplify matters, the actual size of a Torx bit is measured in millimeters. The first digit of the size designation (e.g., T10) represents the major diameter of the bit, which is the distance across the six-pointed star. For instance, a T10 bit has a major diameter of 10 millimeters.

The second digit of the size designation indicates the pitch, which is the distance between the teeth of the star. A larger pitch means wider teeth, while a smaller pitch has tighter teeth. In general, fasteners with a larger major diameter will have a larger pitch to accommodate the increased torque requirements.

For example, a T20 bit has a major diameter of 6 millimeters and a pitch of 4 millimeters, while a T60 bit has a major diameter of 16 millimeters and a pitch of 6 millimeters. Understanding this relationship ensures you select a bit that perfectly fits the fastener, reducing the risk of stripping or damaging either component.

When selecting a Torx bit size, it’s essential to consult the specifications of the fastener you’re working with. Using a bit that’s too small may result in insufficient torque transfer and potential fastener damage, while a bit that’s too large may not fully engage with the star, leading to slippage and frustration.

By mastering the art of Torx bit sizing, you’ll unlock the power to tackle any fastening challenge with precision and efficiency. So, next time you’re reaching for your trusty Torx bits, remember to consult this guide and ensure the perfect fit for a job well done!

Torx Bit Length: A Vital Element in Efficient Fastening

Torx bits, with their six-pointed star-shaped drive, offer superior gripping power and reduced cam-out, making them a popular choice for various applications. One crucial aspect to consider when using Torx bits is their length. The appropriate bit length enhances usability, ensures proper engagement, and prevents damage to both the fastener and the bit itself.

Significance of Bit Length

The length of a Torx bit plays a significant role in determining its suitability for specific tasks. A bit that is too short may not reach the fastener adequately, resulting in poor torque transmission and potential stripping of the screw head. Conversely, an excessively long bit may be unwieldy and prone to bending or breakage, especially when accessing fasteners in confined spaces.

Variations in Length

Torx bits come in various lengths to accommodate a wide range of applications. Common lengths include:

- Short bits (10-25 mm): Ideal for reaching fasteners in tight or recessed areas, such as electronics and appliances.

- Medium bits (25-50 mm): Suitable for general-purpose applications, including furniture assembly and automotive repair.

- Long bits (50+ mm): Designed for accessing deeply recessed fasteners, such as those found in machinery or heavy equipment.

Impact on Application Suitability

Selecting the appropriate Torx bit length depends on several factors:

- Fastener Depth: The bit should be long enough to engage the fastener fully and provide sufficient leverage.

- Accessibility: For fasteners located in tight or obstructed spaces, a shorter bit is more suitable.

- Tool Compatibility: The bit length should match the depth of the driver or socket used.

Understanding the significance of Torx bit length is essential for efficient and safe fastening. Choosing the correct length ensures proper engagement, reduces the risk of damage, and enhances overall usability. By considering the fastener depth, accessibility, and tool compatibility, you can select the optimal Torx bit length for your specific application.

Torx Bit Drive Types: Understanding Compatibility and Usability

In the realm of tightening and loosening fasteners, Torx bits have earned a reputation for their exceptional performance and ease of use. Beyond their distinctive star-shaped design, Torx bits come in a variety of drive types, each catering to specific tools and applications. Understanding these drive types is crucial for ensuring compatibility and efficient use.

Hex Drive: The Classic Choice

Hexagonal drive Torx bits are one of the most common types, characterized by their six-sided shape. This drive fits snugly into hex-shaped bit holders, providing a secure connection for transmitting torque. Hex drives are widely available and compatible with a range of tools, making them a versatile option for general-purpose tasks.

Square Drive: Robust and Reliable

Square drive Torx bits feature a square-shaped hole for insertion into bit holders. Known for their high torque capacity, they can withstand significant force without slipping or deforming. Square drives are often used in industrial and automotive applications where durability is paramount.

Multi-Spline Drive: Versatility and Convenience

Multi-spline drive Torx bits combine multiple splines or grooves around their circumference. This design allows for a higher number of contact points between the bit and bit holder, resulting in increased torque transmission and reduced slippage. Multi-spline drives are particularly useful in situations where access is limited or when working with delicate fasteners.

Compatibility Considerations

It’s important to note that not all Torx bit drive types are compatible with all bit holders. Hex drives are designed to fit hexagonal bit holders, while square drives require square bit holders. Multi-spline drives, on the other hand, may require specialized bit holders designed specifically for their unique design. Failing to use the correct bit holder can lead to improper engagement, damage to the bit or fastener, or potential injuries.

Choosing the Right Drive Type

The best Torx bit drive type for a particular application depends on the specific requirements. For general purposes and where space is not a constraint, hex drives offer a simple and reliable solution. Square drives are ideal for heavy-duty applications where maximum torque is needed. Multi-spline drives provide a combination of versatility and durability, making them suitable for various tasks, including those in confined spaces.

By understanding the different Torx bit drive types and their compatibility, you can ensure that you have the right tools for the job. This will not only enhance your efficiency but also contribute to the safety and durability of your equipment.

Torx Bit Materials: A Material World for Your Torque Needs

When it comes to Torx bits, the choice of material plays a crucial role in determining their durability and performance. Three main types of materials are commonly used: stainless steel, alloy steel, and hardened steel. Each material offers unique advantages and drawbacks, making it suitable for specific applications.

Stainless Steel: A Corrosion-Resistant Choice

Stainless steel is an excellent choice for Torx bits that will be exposed to corrosive environments. Its resistance to rust and chemicals makes it ideal for use in marine applications, food processing, and other industries where moisture and contaminants are present. Stainless steel bits are also known for their durability and long lifespan.

Alloy Steel: The Strength and Balance

Alloy steel is a versatile material that offers a balance between strength and hardness. It is commonly used in Torx bits that require high torque capacity and durability. Alloy steel bits are suitable for general-purpose applications in various industries, including automotive, construction, and manufacturing.

Hardened Steel: Unmatched Hardness and Strength

Hardened steel is the ultimate choice when you need maximum hardness and durability. Torx bits made from hardened steel are subjected to a heat treatment process that increases their surface hardness significantly. These bits are ideal for demanding applications, such as heavy-duty industrial work, where resistance to wear and breakage is paramount.

Material Considerations:

- Corrosion resistance: Stainless steel is the best option for corrosive environments.

- Strength and durability: Alloy steel provides a balance of both.

- Hardness and wear resistance: Hardened steel offers the highest level of resistance.

- Cost: Stainless steel is typically more expensive than alloy steel and hardened steel.

- Application suitability: Match the material to the specific task and environment.

By understanding the different materials used in Torx bits, you can make informed decisions about which type is right for your application. Whether you need corrosion resistance, strength, or extreme hardness, there’s a Torx bit material that meets your requirements.

Torx Bit Head Styles: Unveiling the Intricate World of Fastening

When it comes to fastening solutions, Torx bits stand out for their exceptional gripping power and versatility. But beyond their size, length, and drive types, Torx bits also come in a variety of head styles, each designed for specific applications. Understanding these head styles is crucial for choosing the right bit for the job.

Standard Torx

The standard Torx head style features six-lobed indentations that provide a secure and non-slip fit. Its simplicity and efficiency make it widely used in various industries, including automotive, construction, and manufacturing. Standard Torx bits are suitable for general fastening tasks where high torque is required.

Security Torx

For applications where enhanced security is paramount, Security Torx bits come into play. These bits feature a special pin in the center of the head that prevents unauthorized removal. The unique design makes them ideal for protecting sensitive equipment, preventing theft, and ensuring tamper-proof connections.

Tamper-proof Torx

Tamper-proof Torx bits are designed to resist unauthorized access through their innovative head shape. These bits have a small hole in the center that requires a specialized tool to remove. Tamper-proof Torx bits are commonly used in electronic devices, security systems, and areas where unauthorized tampering is a concern.

Choosing the right Torx bit head style is essential for optimizing performance and ensuring a secure and reliable fastening. By understanding the purpose and applications of each style, you can make informed decisions that meet your specific needs. Whether it’s standard, Security Torx, or tamper-proof Torx, the appropriate bit will help you achieve flawless fastening results every time.

Magnetic Torx Bits: Enhancing Efficiency and Safety

In the realm of fasteners and tools, Torx bits hold a prominent position, renowned for their superior grip and wide-ranging applications. Among the various types available, magnetic Torx bits stand out as indispensable tools for a multitude of tasks. Imbued with exceptional qualities, they offer unrivaled advantages that elevate the user experience to new heights.

Firstly, magnetic Torx bits boast an enhanced gripping power, effortlessly securing fasteners even in the most challenging situations. This exceptional grip prevents slippage and ensures a precise and secure connection. The magnetic feature acts as an invisible hand, holding the fastener firmly in place, allowing for effortless and efficient operation.

Secondly, magnetic Torx bits contribute to increased safety on the worksite. The strong magnetic attraction eliminates the risk of dropped fasteners, which can pose a safety hazard and cause frustration. Especially when working in confined or overhead spaces, the magnetic feature provides peace of mind, ensuring that fasteners remain securely attached to the bit throughout the process.

Furthermore, magnetic Torx bits provide unparalleled convenience. They expedite the fastening process, eliminating the need for time-consuming fumbling with fasteners or the frustration of dropped screws rolling away into inaccessible corners. This translates into increased productivity and time savings, making magnetic Torx bits the perfect choice for applications where efficiency is paramount.

In summary, magnetic Torx bits are an invaluable asset for any toolbox. Their enhanced grip, increased safety, and unparalleled convenience make them the ideal choice for a wide range of fastening tasks. Whether you’re a seasoned professional or a do-it-yourselfer, incorporating magnetic Torx bits into your tool arsenal will undoubtedly enhance your productivity and safety. Embrace the magnetic advantage and elevate your fastening experience today!