This guide provides comprehensive information on selecting the ideal extension ladder size. It covers crucial factors such as length, width, weight, stability, and material. By determining the required reach and considering weight and stability, users can choose a ladder that ensures both safety and functionality. The guide discusses the pros and cons of different materials, including aluminum, fiberglass, and wood. It also highlights additional features like adjustable feet, safety cages, and tool hooks that enhance ladder usability and safety.

Choosing the Ideal Ladder: A Guide to Length and Height Considerations

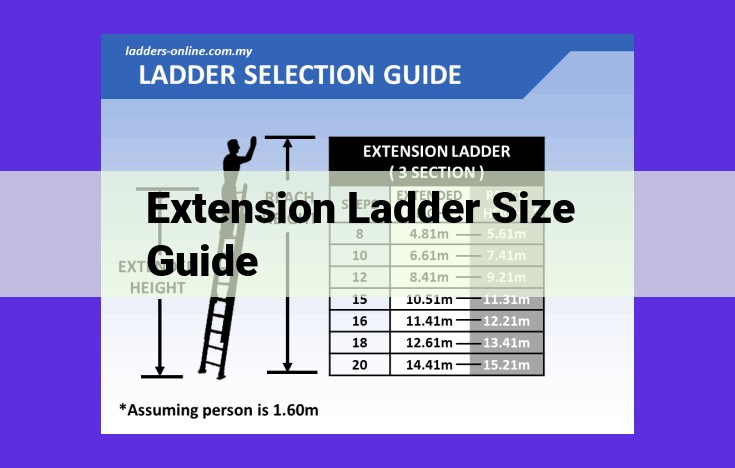

Before embarking on your ladder selection journey, it’s crucial to determine the required reach for your intended tasks. This involves taking into account not only the height you need to access but also your own height and weight.

Consider the following scenario: You’re painting the exterior of a two-story home. The peak of the roof is 20 feet high, and you’re 5’10” tall. To comfortably reach the top, you’ll need a ladder that allows you to stand about 3-4 feet above the peak. This means you’ll need a ladder with a reach of approximately 24-28 feet.

Material also plays a role in determining the appropriate ladder length and height. Aluminum ladders are typically lighter and more compact than fiberglass or wood ladders. This makes them easier to maneuver and handle, especially when working at heights. However, fiberglass ladders offer greater insulation and are ideal for electrical work. Wood ladders, on the other hand, are robust and durable but require more maintenance and are heavier than aluminum or fiberglass.

By considering your height, weight, and material preferences, you can narrow down your choices and select the ladder that best meets your specific requirements.

Width and Stability: The Balancing Act of Ladder Safety

Navigating the vast array of ladders on the market can be a daunting task, especially when considering the interplay between width and stability. These two factors go hand in hand, influencing the ladder’s overall safety and functionality. Understanding their relationship is paramount to ensuring a sturdy and reliable ladder for your specific needs.

Width: A Balancing Force

The width of a ladder plays a crucial role in its stability. A wider ladder provides a more stable base, allowing it to withstand lateral forces and uneven surfaces without tipping over. This is especially important for tasks involving high elevations or heavy equipment.

Conversely, a narrower ladder may be suitable for confined spaces or applications where weight is a primary concern. However, it is essential to remember that narrower ladders sacrifice some stability in exchange for portability.

Weight and Material: The Stability Equation

The weight of the ladder also impacts its stability. Heavier ladders are typically more stable, as they have a lower center of gravity. However, lighter ladders may be easier to handle and transport, making them suitable for tasks where mobility is essential.

The material of the ladder also plays a role in its overall weight and stability. Aluminum ladders are lightweight and durable, while fiberglass ladders are strong and non-conductive. Wood ladders offer a balance of strength and affordability.

The Takeaway: Striking the Perfect Balance

Choosing the right ladder width and stability for your needs requires careful consideration of the task at hand, the weight you will be carrying, and the material that best suits your preferences. A wider ladder with a heavier weight and a sturdy material will provide the highest level of stability, while a narrower, lighter ladder may be more suitable for portability and confined spaces.

Always prioritize safety when choosing a ladder, and remember that the ideal width and stability will vary depending on your specific application. By understanding the relationship between these factors, you can confidently select the ladder that meets your unique requirements.

Weight and Portability: A Balancing Act for Ladder Selection

Weight plays a crucial role in the handling, stability, and material selection of ladders. It’s a balancing act that requires careful consideration for both convenience and safety.

Impact on Handling:

The weight of a ladder significantly affects its ease of use. Lightweight ladders, often made of aluminum or fiberglass, are easier to lift and maneuver, especially for extended periods. This is particularly beneficial for tasks like painting or electrical work, where the ladder needs to be moved frequently.

Influence on Stability:

Weight also influences the stability of a ladder. Heavier ladders, typically made of wood or steel, offer greater stability, especially when supporting heavier loads or on uneven surfaces. Conversely, lighter ladders may be more prone to swaying or tipping, making them better suited for less demanding tasks.

Material Considerations:

The weight of a ladder is closely tied to its material composition. Aluminum ladders are lightweight and durable, making them a popular choice for portable use. Fiberglass ladders offer a good balance between weight and strength, while wood ladders are typically heavier but provide excellent stability.

Material Considerations for Selecting the Perfect Ladder

When choosing a ladder, the material plays a pivotal role in determining its durability, weight, and safety attributes. Here’s a breakdown of the advantages and limitations of the three most common ladder materials:

Aluminum

- Advantages: Aluminum ladders are incredibly lightweight and easy to handle, making them ideal for tasks where portability is essential. They are also resistant to corrosion and require minimal maintenance.

- Limitations: While aluminum ladders are sturdy, they can be subject to bending or cracking under heavy loads. Additionally, they can conduct electricity, posing a safety hazard when working near electrical wires.

Fiberglass

- Advantages: Fiberglass ladders offer exceptional strength and durability. They are also non-conductive, making them safe for working near electricity. Fiberglass is highly resistant to chemicals and moisture, ensuring long-term performance.

- Limitations: Fiberglass ladders are heavier than aluminum, which can make handling and storage more challenging. They can also be more expensive than aluminum ladders.

Wood

- Advantages: Wood ladders are natural insulators, making them suitable for electrical work. They are also relatively inexpensive and can be easily repaired or replaced.

- Limitations: Wood ladders are susceptible to rot, decay, and insect infestation. They are also heavier and bulkier than aluminum or fiberglass ladders, making them less portable. Additionally, wood ladders require regular maintenance to prevent warping or cracking.

Choosing the right ladder material depends on the specific needs of your project. Consider the length, weight, stability, and safety requirements to make an informed decision. By understanding the advantages and limitations of each material, you can select the ladder that best meets your needs and ensures your safety at all times.

Innovative Features for Enhanced Ladder Functionality and Safety

When it comes to selecting the ideal ladder for your project, additional features play a significant role in elevating its functionality and ensuring your well-being. These thoughtful details not only enhance convenience but also contribute to increased safety measures.

Adjustable Feet

*Ladders with _adjustable feet_** allow for secure and stable positioning on uneven surfaces. This feature is particularly advantageous when working on sloped terrain or when the base of the ladder is not level. By adjusting the height of each foot, you can create a solid and stable foundation, preventing wobbles or potential slips.

Safety Cages

For tasks involving extended periods of overhead work, safety cages provide a valuable layer of protection. These sturdy enclosures surround the top of the ladder, creating a safe and enclosed space for the user. Safety cages minimize the risk of falls and provide peace of mind, allowing you to focus on the task at hand without worry.

Tool Hooks

Tool hooks are an essential addition for efficient and organized ladder work. These handy attachments provide convenient storage for tools and materials, keeping them within easy reach. By eliminating the need to constantly climb down the ladder, tool hooks streamline your workflow and enhance productivity.

In addition to these key features, other thoughtful details can further enhance ladder functionality. These include:

- Wide, slip-resistant rungs for secure footing

- Reinforced side rails for increased stability

- Non-marking feet to protect delicate surfaces

Choosing a ladder that incorporates these additional features ensures a safer, more comfortable, and efficient work experience. By investing in a ladder that meets your specific needs and incorporates these innovative enhancements, you can elevate your project to a new level of success.