- Comprehensive scaffolding assembly guide ensuring safety and compliance with essential regulations and best practices.

- Detailed materials and assembly sequence with troubleshooting tips to ensure stability and accuracy.

- Inspection and sign-off procedures for verifying safety and mitigating risks, with best practices for maintenance and troubleshooting challenges.

- Emphasis on safety protocols, training, certifications, and quality control to enhance professionalism and ensure adherence to guidelines.

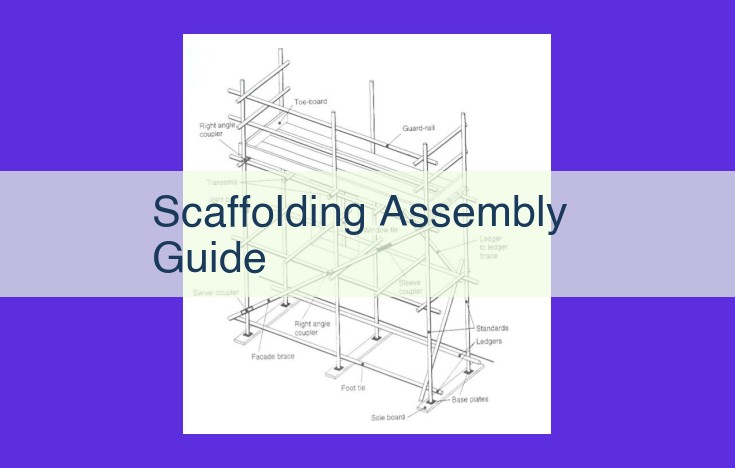

- Step-by-step assembly instructions and visual guides for clarity and error prevention.

- Summary of key points and the importance of adherence to minimize risks and promote safety in scaffolding assembly.

Comprehensive Scaffolding Assembly Guide: A Safety-First Approach

Scaffolding plays a crucial role in construction and maintenance projects, providing a safe and efficient platform for workers to reach elevated areas. However, improper assembly can lead to accidents and severe injuries. This guide will provide a comprehensive overview of the importance and best practices for scaffolding assembly, ensuring a safe and compliant workplace.

-

Importance and Overview of Proper Scaffolding Assembly Guidelines:

- Adhering to proper assembly guidelines is essential for ensuring the safety and stability of scaffolding.

- Guidelines provide detailed instructions on the use of materials, assembly sequence, and safety regulations.

-

Essential Safety Regulations and Best Practices:

- Follow industry standards and OSHA regulations: These regulations provide comprehensive guidance on scaffolding assembly and use.

- Use appropriate materials: Select high-quality materials that meet specific load-bearing requirements and are resistant to corrosion.

- Plan and prepare before assembly: Assess the work area, identify potential hazards, and develop a clear assembly plan.

Materials and Assembly Sequence: The Foundation of Stability

When it comes to scaffolding assembly, the materials you use and the sequence you follow are paramount for stability. Let’s delve into the critical components and step-by-step instructions to ensure a rock-solid foundation:

Critical Components: The Building Blocks

- Standards: Vertical support beams that bear the weight of the platform.

- Ledgers: Horizontal beams that connect standards, providing stability and support for the platform.

- Braces: Diagonal members that prevent the scaffolding from swaying or collapsing.

- Platforms: The work surfaces for accessing the work area.

- Toeboards: Boards installed around the edges of platforms for fall prevention.

Troubleshooting Material Issues:

- Damaged or weakened components: Replace immediately.

- Missing or incorrect fasteners: Use the correct size and type for optimal strength.

- Corrosion or rust: Treat with anti-rust solutions or consider replacement.

- Improperly cut or sized materials: Ensure they meet specifications to prevent instability.

Step-by-Step Assembly: A Precise Dance

1. Base Level:

* Place toeboards around the perimeter of the base platform.

* Install standards upright and secure with ledgers.

* Install braces diagonally to create stability.

2. Subsequent Levels:

* Repeat step 1 for each subsequent level.

* Connect new levels to the existing structure with couplers and ledgers.

* Stagger vertical and diagonal bracing for maximum rigidity.

3. Final Touches:

* Install guardrails around the platform edges for fall protection.

* Inspect the entire structure for defects and tighten all connections.

* Obtain approval from a qualified inspector before use.

By meticulously following these instructions, you ensure a stable and safe scaffolding structure that can withstand the rigors of any project. Remember, precision is key to preventing accidents and maintaining the integrity of your work environment.

Inspection and Sign-Off: Verifying Safety and Compliance

Ensuring the safety and compliance of scaffolding structures requires a thorough and well-documented inspection and sign-off process. Pre-assembly inspections play a crucial role in verifying the integrity of components and identifying potential hazards. These inspections should be conducted by qualified personnel trained in scaffolding assembly and safety regulations.

During post-assembly inspections, the focus shifts to verifying the proper assembly and overall stability of the structure. Inspectors scrutinize connections, bracing, and platforms for any deviations from assembly guidelines. Common deficiencies to look out for include loose bolts, misaligned frames, and improperly installed guardrails.

To ensure a comprehensive evaluation, inspectors should meticulously document their findings on an inspection checklist. This checklist should include detailed descriptions of any deficiencies, along with recommended corrective actions. The sign-off process should be completed only after all deficiencies have been addressed and the scaffolding is deemed safe for use.

Best Practices for Inspection and Sign-Off:

- Establish clear inspection criteria and checklists for both pre- and post-assembly inspections.

- Train and certify inspectors on proper scaffolding assembly and safety regulations.

- Maintain accurate inspection records and ensure that sign-offs are completed by authorized personnel.

- Regularly review and update inspection procedures to align with industry best practices and evolving safety standards.

- Encourage open communication between inspectors and assembly crews to address concerns and ensure compliance.

By adhering to these best practices, organizations can create a culture of safety and ensure that their scaffolding structures meet the highest standards of quality and compliance.

Safety Protocols for Troubleshooting: Addressing Assembly Challenges

Troubleshooting scaffolding assembly issues requires a keen eye, a steady hand, and unwavering adherence to safety protocols. As you navigate potential assembly roadblocks, it’s crucial to prioritize your safety and approach the task with a meticulous and controlled mindset. Let’s delve into some common assembly problems and the safety guidelines you should follow to address them effectively:

Unstable Base

If your scaffolding is shaky or appears unstable, immediately cease all work and evacuate the area. Inspect the base for uneven ground, loose or missing components, and ensure it is adequately secured. Never attempt to stabilize a shaky structure by adding weight or makeshift supports.

Loose Connections

Inspect all nuts, bolts, and pins for tightness. Use a torque wrench to ensure they are secured to the manufacturer’s specifications. This seemingly minor issue can lead to catastrophic consequences if left unattended, so do not skip this critical step.

Overloading

Exceeding the load capacity of your scaffolding is a serious safety hazard. Never overload the platform with materials or personnel. Check the manufacturer’s specifications and clearly mark the maximum load capacity in a visible location.

Improper Assembly

If you encounter resistance or misalignment during assembly, stop and consult the scaffolding manual or seek guidance from a qualified professional. Attempting to force components into place can weaken the structure and create a dangerous situation.

Damaged Components

Inspect all scaffolding components thoroughly for damage or defects before assembly. Do not use damaged parts. Even small cracks or dents can compromise the integrity of the scaffolding.

Safety Guidelines

- Wear appropriate personal protective equipment (PPE), including a hard hat, safety glasses, and non-slip footwear.

- Use proper lifting techniques and avoid overexertion when handling heavy components.

- Work with a spotter if necessary to ensure your safety.

- Maintain a clean and organized work area free from trip hazards.

- Supervise all assembly work to prevent unauthorized changes or improper practices.

Remember, safety is paramount in scaffolding assembly. By following these guidelines and approaching potential issues with a risk-minimizing mindset, you can ensure a safe and successful scaffolding project.

**Best Practices and Certifications: Enhancing Scaffolding Assembly Skills and Professionalism**

Ensuring Expertise and Safety in Scaffolding Assembly

Proper scaffolding assembly is critical to protect workers and ensure the stability of these temporary structures. To achieve the highest levels of safety and efficiency, it’s essential to adhere to industry best practices and obtain relevant certifications.

Essential Assembly Guidelines

Assembling scaffolding requires a methodical and systematic approach. Adhering to established guidelines is paramount to minimize risks and ensure the integrity of the structure. These guidelines cover proper material handling, component selection, and the sequence of assembly. By diligently following these procedures, scaffolding professionals can avoid potential hazards and ensure a safe working environment.

Importance of Training and Certification

Formal training is indispensable for scaffolding assemblers. Certified professionals have undergone rigorous instruction and have a thorough understanding of the industry standards, safety regulations, and best practices. This knowledge empowers them to make informed decisions, identify potential hazards, and respond effectively to emergencies.

Quality Control and Maintenance

Quality control is an ongoing process that ensures scaffolding structures meet the highest safety standards. Regular inspections and maintenance are essential to identify and address any deterioration or damage. By implementing a robust quality control system, companies can proactively mitigate risks and maintain the integrity of their scaffolding structures.

The pursuit of excellence in scaffolding assembly is a commitment to safety, compliance, and professional development. By incorporating best practices, training, certification, and quality control measures, scaffolding professionals can elevate their skills, demonstrate their expertise, and foster a safe working environment for all.

Quality Control: Maintaining the Highest Standards in Scaffolding Assembly

Ensuring Safety and Compliance

Scaffolding structures play a crucial role in construction and maintenance projects, providing safe access to elevated areas. Maintaining the highest standards of quality control is paramount to ensure the safety of workers and minimize risks throughout the assembly process.

Safety Guidelines and Inspection Procedures

Establishing clear safety guidelines is essential for quality control. Regular inspections at critical stages of assembly ensure that all components meet specifications and adhere to industry regulations. Pre-assembly inspections verify the integrity of materials and components, while post-assembly inspections ensure stability and compliance with load limits.

Best Practices for Compliant Structures

To maintain compliant scaffolding structures, best practices should be implemented throughout the assembly process. These include using only certified materials, following manufacturers’ guidelines precisely, and ensuring proper maintenance and repair. Regular inspections identify potential issues and allow for timely corrective actions to prevent incidents.

Inspection Criteria and Documentation

Inspections should focus on critical elements such as joints, bracing, and load-bearing capacity. Inspectors should be trained and experienced to identify any deviations from specifications or safety standards. Thorough inspection records provide evidence of compliance and facilitate proper documentation for traceability and liability purposes.

Continuous Monitoring and Evaluation

Quality control involves continuous monitoring and evaluation of scaffolding structures throughout their lifespan. This includes regular inspections, observing usage patterns, and addressing any reported concerns. By proactively identifying and addressing potential issues, risks are minimized, and the integrity of the scaffolding is maintained.

Adhering to a comprehensive quality control program is essential for maintaining compliant and safe scaffolding structures. By following safety guidelines, implementing best practices, and conducting thorough inspections, construction professionals can ensure the highest standards of quality and minimize risks throughout the assembly process. This not only protects the safety of workers but also enhances project efficiency and compliance with industry regulations.

Step-by-Step Assembly Instructions: A Visual Guide to Success

To delve into the intricate world of scaffolding assembly, let us embark on a pictorial journey that will unravel the secrets of building a sturdy and safe structure. Armed with our detailed assembly sequence, we will navigate the process with unwavering clarity. As we progress, we will unearth troubleshooting tips and common assembly challenges, ensuring that you can gracefully sidestep any hurdles that may arise.

Laying the Foundation: Materials and Base

Begin by gathering the essential components of your scaffolding system: frames, braces, platforms, and ladders. Scrutinize each component carefully, ensuring that they meet industry standards and are free from defects. Check for any loose or damaged parts, as these could compromise the integrity of the structure. Next, select a level and stable base for your scaffolding. Uneven ground can create instability, posing a significant safety risk.

Assembling the Framework: Frames and Braces

With your base firmly in place, it is time to assemble the framework of your scaffolding. Connect the frames together using the provided pins or bolts, ensuring that they are aligned precisely. Install horizontal and diagonal braces to provide stability and rigidity to the structure. Secure the braces tightly, preventing any movement or swaying.

Installing Platforms and Ladders: Access and Work Surfaces

Now, it is time to add platforms to create work surfaces. Ensure that the platforms rest securely on the frames and are adequately secured to prevent any slippage or movement. Install ladders to provide access to different levels of the scaffolding, ensuring that they are sturdy and firmly anchored.

Double-Checking and Final Touches

Before you ascend the scaffolding, thoroughly inspect the entire structure once again. Look for any loose connections, unsecured braces, or damaged components. Test the stability of the scaffolding by applying pressure to different sections. If any adjustments or repairs are necessary, make them promptly.

Safety First: Inspection and Maintenance

Remember, the safety of your crew and the integrity of your scaffolding rely on regular inspections and maintenance. Conduct thorough inspections before and after each use, paying particular attention to connections, braces, platforms, and ladders. Document all inspections and address any deficiencies immediately. Routine maintenance will help extend the lifespan of your scaffolding and mitigate potential hazards.

By following these step-by-step instructions and adhering to safety protocols, you can construct a scaffolding structure that meets industry standards and ensures the well-being of your team. Remember, safety is paramount in the realm of scaffolding assembly.

Ensuring Safety Throughout: A Risk-Minimizing Approach

Maintaining vigilance is paramount when working on or around scaffolding. To minimize risks and ensure utmost safety, regular inspections and a stringent sign-off process are essential.

Pre-assembly inspections thoroughly scrutinize the scaffolding components for any defects or damage. Thorough checks of bolts, nuts, and joints ensure structural integrity. Post-assembly inspections verify the correct assembly and adherence to safety standards.

Safety-conscious workers should always inspect the scaffolding before using it. Look for any loose connections, damaged planks, or other potential hazards. If any deficiencies are detected, report them immediately to a supervisor or designated safety officer.

Clear communication and proper documentation are vital for safety. All inspections should be recorded and signed off by authorized personnel. This creates a paper trail that documents the scaffolding’s condition and ensures accountability.

Supervisors and project managers have the responsibility to ensure that all workers are trained and certified in proper scaffolding assembly and safety protocols. Ongoing training reinforces best practices and keeps workers up-to-date on the latest safety regulations.

Creating a safe working environment extends beyond the scaffolding itself. Adequate lighting, proper ventilation, and clear access to the work area are essential. Eliminating tripping hazards and providing fall protection equipment further minimizes risks.

By implementing these measures, contractors can create a comprehensive safety plan that safeguards workers and reduces the likelihood of accidents. Adhering to industry standards and best practices is not just a matter of compliance, but a testament to a workplace that values safety above all.