Brake horsepower (BHP) measures an engine’s net power output, considering factors like indicated horsepower, mechanical efficiency, friction horsepower, auxiliary horsepower, and gross horsepower. BHP is influenced by engine design, combustion efficiency, frictional losses, and accessory power requirements, and it’s crucial for calculating engine efficiency, determining performance, and diagnosing issues. Optimizing BHP involves enhancing engine design, maintenance, and tuning to minimize losses and maximize power output, ultimately improving vehicle performance and fuel economy.

Understanding Brake Horsepower: A Measure of Engine Performance

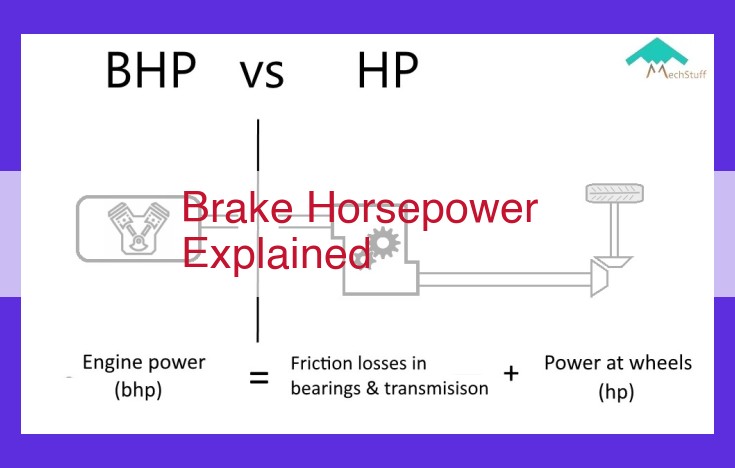

Brake horsepower (BHP) is a crucial metric in assessing the net power output of an engine. It measures the actual power delivered to the drivetrain after accounting for internal losses. BHP is a direct indication of an engine’s capability and efficiency.

In simpler terms, BHP represents the amount of usable power available to propel the vehicle forward. It excludes power absorbed by internal components, such as the friction of moving parts and the operation of accessories like water pumps and alternators.

Understanding the Relationship: BHP and Related Concepts

BHP is closely related to other engine performance concepts:

- Indicated Horsepower (IHP): Theoretical power output without considering internal losses.

- Mechanical Efficiency: The ratio of BHP to IHP, representing how efficiently the engine converts fuel energy into usable power.

- Friction Horsepower (FHP): Power lost due to friction between moving parts.

- Auxiliary Horsepower (AHP): Power consumed by accessories.

- Gross Horsepower (GHP): Total power output before accounting for internal losses.

These concepts help us understand how BHP is influenced by engine design, combustion efficiency, frictional losses, and accessory power requirements.

Factors Affecting BHP

BHP can be affected by various factors, including:

- Engine design and configuration

- Combustion efficiency and fuel quality

- Frictional losses in moving parts

- Accessory power requirements such as alternators and air conditioning

Applications of BHP

BHP is used in numerous automotive applications, including:

- Calculating engine efficiency and diagnosing issues

- Determining vehicle performance and power-to-weight ratios

- Comparing engines and evaluating their suitability for specific applications

Optimizing BHP

Optimizing BHP can enhance engine performance and efficiency. Here are some strategies:

- Use low-friction components and advanced lubricants

- Improve combustion efficiency through optimized fuel injection and ignition systems

- Reduce parasitic losses by using efficient accessories

- Consider engine modifications and tuning for improved power output

Related Concepts

Beyond Brake Horsepower (BHP), there are several related concepts that provide a comprehensive understanding of engine performance:

-

Indicated Horsepower (IHP): This represents the theoretical maximum power that could be generated by the engine if there were no losses due to friction or other inefficiencies. It is calculated based on the pressure and volume changes within the cylinders.

-

Mechanical Efficiency: This is the ratio of BHP to IHP, expressed as a percentage. It indicates how much of the theoretical power is actually realized at the output shaft of the engine. Losses due to friction, pumping, and other internal factors reduce mechanical efficiency.

-

Friction Horsepower (FHP): This represents the power lost due to friction between moving parts within the engine, such as the pistons, bearings, and valve train. FHP is typically measured using a dynamometer.

-

Auxiliary Horsepower (AHP): This is the power required to operate auxiliary components such as the water pump, oil pump, alternator, and power steering pump. These components consume power from the engine, further reducing the amount available at the output shaft.

-

Gross Horsepower (GHP): This is the total power produced by the engine before any accessories or losses are accounted for. GHP includes BHP, FHP, and AHP.

These concepts help provide a comprehensive view of engine performance and efficiency. Understanding the relationships between them allows for better analysis of engine behavior, diagnostics of issues, and potential improvements.

Understanding the Relationship: BHP and Its Interdependent Concepts

Brake horsepower (BHP), a measure of an engine’s net power output, is intricately intertwined with several other key concepts. To fully grasp BHP, it’s essential to understand the interplay between these concepts:

-

Indicated Horsepower (IHP): IHP represents the theoretical power output if an engine’s combustion cycle were 100% efficient.

-

Mechanical Efficiency: This measures the efficiency of converting IHP into BHP, accounting for frictional losses within the engine.

-

Friction Horsepower (FHP): FHP represents the power lost to friction between moving components in the engine, such as pistons and bearings.

-

Auxiliary Horsepower (AHP): AHP is the power required to operate engine accessories like water pumps and alternators.

-

Gross Horsepower (GHP): GHP is the total power output of an engine, including both BHP and AHP.

These concepts form a complex relationship, where changes in one can significantly impact the others:

-

BHP is influenced by IHP: Higher IHP leads to higher BHP, as more power is generated from the combustion process.

-

BHP is impacted by Mechanical Efficiency: Lower mechanical efficiency means more power is lost to friction, reducing BHP.

-

BHP is affected by FHP: Increased frictional losses result in lower BHP, as more power is consumed in overcoming friction.

-

BHP is influenced by AHP: When accessories demand more power, BHP decreases as less power is available for propulsion.

-

GHP is determined by BHP and AHP: As both BHP and AHP contribute to the total power output, changes in either will affect GHP.

Understanding these interdependencies is crucial for analyzing engine performance. BHP is the most important measurement of engine power, as it represents the power available for the vehicle to utilize. By considering the relationships between BHP and its related concepts, engineers and mechanics can optimize engine performance, diagnose issues, and improve efficiency.

Factors Affecting Brake Horsepower (BHP)

Engine Design:

The design of the engine plays a crucial role in determining its BHP. Factors like the number of cylinders, displacement, compression ratio, valve timing, and camshaft profile directly influence the engine’s ability to generate net power.

Combustion Efficiency:

The efficiency of combustion is another key factor affecting BHP. Incomplete combustion due to factors like poor fuel-air mixture, inefficient ignition, or improper valve timing leads to power loss. Optimizing combustion through proper fuel injection, ignition timing, and engine management systems can significantly enhance BHP.

Frictional Losses:

Frictional losses in the engine consume a portion of the power generated. Friction between moving parts like pistons, rings, and bearings reduces the amount of power available at the crankshaft. Minimizing friction through proper lubrication, honing of engine components, and reducing parasitic drag can improve BHP.

Accessory Power Requirements:

Modern engines incorporate various accessories like water pumps, oil pumps, and power steering pumps that require power to operate. The demand for auxiliary power can reduce BHP output. Careful selection of low-power-consuming accessories and efficient design of ancillary systems can help optimize BHP.

By understanding and addressing these factors, engineers and mechanics can optimize engine design, improve combustion efficiency, reduce frictional losses, and minimize accessory power requirements. This holistic approach leads to increased BHP, improved engine performance, and enhanced fuel economy.

Applications of Brake Horsepower (BHP): A Key Metric for Engine Performance

BHP isn’t just a number; it’s a vital performance indicator that reveals the true power of your engine. Understanding its applications is crucial for maximizing engine efficiency, optimizing performance, and identifying potential issues.

-

Calculating Engine Efficiency: BHP plays a central role in determining the efficiency of your engine. By comparing BHP to fuel consumption, you can assess how efficiently your engine converts fuel into usable power. A higher BHP-to-fuel consumption ratio indicates better engine efficiency.

-

Determining Engine Performance: BHP is a direct measure of the net power output of your engine. It represents the actual power available to propel your vehicle, drive machinery, or perform other tasks. By comparing BHP values, you can gauge the performance of different engines or track changes in performance over time.

-

Diagnosing Engine Issues: Deviations from expected BHP levels can indicate underlying engine problems. For instance, a sudden drop in BHP may signal issues with fuel injection, ignition, or mechanical components. By monitoring BHP and comparing it to reference values, you can pinpoint the source of problems and initiate timely repairs.

Understanding the applications of BHP empowers you to:

- Monitor engine health and detect potential problems early on

- Optimize engine performance for better efficiency and responsiveness

- Make informed decisions regarding engine maintenance and upgrades

Embrace BHP as your trusted guide to engine performance and efficiency. By harnessing its insights, you can unlock the full potential of your engine and keep it running smoothly for years to come.

Optimizing Brake Horsepower (BHP) for Enhanced Engine Performance

Understanding brake horsepower (BHP) and its contributing factors is crucial for maximizing engine efficiency and performance. Here are some tips and strategies to optimize BHP:

Engine Design Enhancements

Engine design plays a pivotal role in BHP optimization. Implementing efficient combustion chambers, optimizing intake and exhaust systems, and employing low-friction components can significantly improve power output. Engineers strive to reduce parasitic losses by incorporating lightweight materials and reducing rotating mass. Advanced valve timing and variable valve lift technologies can further enhance BHP by optimizing airflow and valve timing.

Maintenance and Upkeep

Regular maintenance is paramount for maintaining optimal BHP. Proper lubrication ensures minimal friction and wear, while air filter replacements optimize airflow into the engine. Spark plug maintenance and ignition system checks prevent misfires and power loss. Regular injector cleaning and fuel system maintenance ensure efficient fuel delivery and combustion. Neglecting these aspects can lead to reduced power and diminished fuel economy.

Performance Tuning

For enthusiasts seeking extra power, performance tuning can unlock the full potential of the engine. Engine remapping adjusts fuel injection, ignition timing, and boost pressure to optimize performance. Upgrading air intakes and exhaust systems can further increase airflow, resulting in improved BHP. However, it’s crucial to seek professional assistance when performing performance tuning to avoid compromising engine reliability and longevity.

Optimizing BHP requires a comprehensive approach encompassing engine design, maintenance, and tuning. By addressing various factors that influence BHP, you can enhance engine performance, improve fuel efficiency, and extend the life of your vehicle. Understanding the concepts and strategies outlined above empowers you to make informed decisions and maximize the capabilities of your engine.